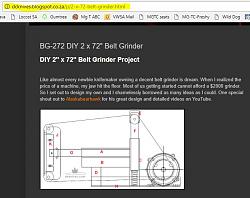

Started my 72 x 2 Belt sander. I am not going to make knives, but I think it can be usefull for all the notching I have to do. The better the fit the easier and stronger the weld. I TIG all my suspension linkages.

I did not use square tubing because the fit of one tube into the other is too loose, so I machined down some 50 x 50 x 5 angle iron to give me a nice snug fit for the 38 x 38 x 4 square tubing I use to slide into the other manufactured tube. I inserted some 0.5mm spacers before welding up the angles to form the tube.

A friend of mine suggested I add some hinges so it is easy to flip it 90 Deg so the belt will run horizontally.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks