A couple of weeks back jjr2001 posted a great simple idea for a holder for number and letter punches. http://www.homemadetools.net/forum/h...622#post104816

The next morning I pulled a small piece out of the aluminium scrap box and made a close copy.

Click on the thumbnails for full size pictures.

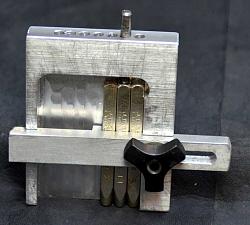

Here is my version, I saw no reason to make it any different to jjr2001's.

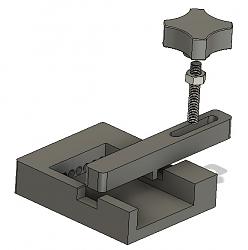

As expected that turned out to be a great help to keep the punches square to a flat work surface. However I often need to punch several numbers in a line and with even spacing. More often than not the row of numbers will be quite wobbly. I needed a tool to help and I started thinking about it after making the copy of jjr2001's. I don't like to spend too much time making tools because my main interest is using tools, so I wanted a simple idea and it came to me when trying to get to sleep last night. It is very simple and took very little time to make. It basically consists of two pieces of aluminium, the scrap box yielded those without needing their external dimensions being changed. A little milling and drilling was all it took.

Here are the two main pieces, the minimum amount of machining is evident.

The assembled tool complete, empty and loaded with 3 punches. It can take up to 7 punches.

The clamping bar is moved to the right so that the protruding piece holds the punches up against one another. The wing nut clamps the bar.

Ready to use, note the 5 mm round rod (made from a broken drill bit) which is used to allow one punch at a time to be hit.

This holder was made for 1/4" punches but it is only a question of scaling to accommodate any size. It would be next to impossible to be able to hit multiple punches with equal force without building a much more complex tool. That is the reason for the upper circular guide holes and a secondary round punch. The secondary punch can be moved from one letter/number punch to another as each indentation is made.

One disadvantage of stacking the punches side by side is that the centre distance between the characters is the same as the width of the punches, 1/4" in my case. That might be too wide in some cases. There are various ways around this which I'll leave to the ingenuity of any readers who make their own.

I did some videoing whilst making and using the device which I'll post when I've made one out of various clips.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks