New plans added on 01/06/2025: Click here for 2,686 plans for homemade tools.

durrelltn (Jan 24, 2023), nova_robotics (Jan 24, 2023)

These space frame roof structures are inherently among some of the lightest structures for a clear span roof system but the size of the building makes them nearly impossible to be hoisted in place by a single crane, sometimes even 4 cranes are not enough to do the lift. I've not seen one that required as many as 6 cranes let alone 8 of them. Coordinating 4 is as bad as it may seem, you just have to have operators who can follow instructions and only 1 person giving the orders.

By far the best way to assemble a space frame system is on the ground unless it has multiple levels then yuoo just need ot have good removable supports as you assemble it. Designing them to have a natural arch increases the stability though.

Then we covered with standing seam roofing we formed on site

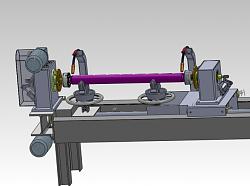

And a drawing of the jig for drilling and threading the ball that the space framework uses for directional connecting.

The welding lathe for making the tubes

Never try to tell me it can't be done

When I have to paint I use KBS products

Inner (Jan 25, 2023), KustomsbyKent (Jan 26, 2023)

Won't work with space frame construction or at least normally it is not economically feasible even factoring in the crane rental, unless you can carpet the entire area under the proposed roof with scaffolding and a near solid platform covering too many 1000s of connections, otherwise it will take forever to assemble. When assembling on the ground you can throw 20 labors at it, and be done fairly quickly, a 20 can do in a day, that would take 10 guys over 3 weeks to do in the air. Installing in smaller more easily manageable sub-assemblies works well providing you have enough Jack stand like supports tall enough strong enough stable enough and with enough height adjustment, However the final adjustment to insure each connection is under equal stress becomes more difficult but not impossible we had to di that way sometimes WHAT A PITA, Not to forget, every connection must be physically inspected for adjustment and tightness try to get an inspector to go over every connection in the air when it is impossible to position a man lift directly under or even near all of the connections,

What they did wrong here was all of the cranes had their booms fully extended and were not sized correctly for the lift When you have a lift that requires more than a single crane both cranes must be strong enough to hold the whole load safely even if the size dictates that is impossible to do 4 cranes means any 2 of them must be capable of the entire lift plus a safety factor the requirements do not lessen as more cranes are employed it still boils down to 1 or 2 cranes being capable of holding the load in static

Never try to tell me it can't be done

When I have to paint I use KBS products

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks