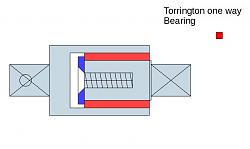

I wanted to be able to start a bike engine while the machine is mounted on a work bench. The kick start is not an option unless you are a giant, so came up with this. After fitting electronic ignition it needs to be strobed to get it correct at full advance which means running up to 4000 rpm while adjustments are made. After researching starter clutches they are mostly based on some form of ratchet or sprag based designs, having had some experience of Torrington one way bearings in use on cylindrical grinding machines namely Jones & Shipman in one of the workhead drive pulleys I decided this would be the simplest approach.

Based on a Torrington one way bearing powered by a high torque drill. This uses standard ½ inch drive sockets and is reversible end for end if needed so can be used for any motor I am working on. I sacrificed an old extension bar which was too hard to mill so I used my filing rest for the hexagon part which fits in the drill chuck.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks