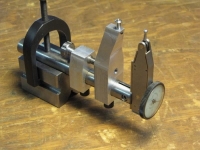

A recent task involved drilling a hole in a key too odd-shaped to grip in the mill vise and thin enough to need support while drilling. Hand holding was out of the question - too dangerous if the drill caught in the brass.

What I needed was a finger plate. I had seen the iconic British form of the device and, elegant as it is, I felt it lacked a bit of the versatility and expandability I like in jigs I intend to keep and use in the future.

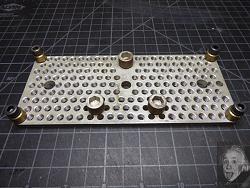

I remembered that I had more of the perforated tooling plate stock that I had used with my miniature milling table...

Miniature milling table

I found a piece in which I had long ago threaded all the holes 1/4-20 (my standard thread for multi-use jig stuff)...

The bottom of a finger plate should be useful too. I had fitted this plate with three SHCS arranged in a triangle. This allows me to hold the plate in three different orientations in the bench vise; makes tasks like filing and sawing easier to perform without contortions. Since things can be screwed to the bottom as well as the top, I put a SHCS at each corner with surplus bronze bearings as spacers. These feet make the plate nice and steady when used on the bench for soldering tasks. The spacers make the legs slightly longer than the triangle screws so the plate rests only on the feet. Also, elevating the plate with these feet allows drilling through holes without fear of marking whatever is supporting the plate.

The next step was to assemble a kit of clamping parts, studs, nuts, etc. A surplus fishing tackle box with dividers provided some storage for the smaller bits...

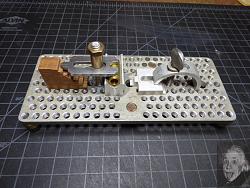

And here's the glamor shot with some clamping examples set up on the plate.

I regard the plate as a semi-consumable. I won't drill into it willy-nilly but, if a hole is needed for a legitimate purpose I'll plan it into the layout and try to think of how it might be made another "feature".

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks