Recently Sam posted about using a Fridge compressor as a vacumn pump at http://www.homemadetools.net/forum/h...ht=vacuum+pump

As well as these units being useful as they are, they contain nice little induction motors which can be useful in their own right.

Click on thumbnails for full size.

These pix show the motor with the pumping cylinder cast into the bearing housing. Note that the rotor is only supported in bearings at one end. The output shaft has a single sided crank to drive the piston. The other end of the shaft is extended and is tapered. It was a while ago when I extracted this motor from its case and I don't recall if that shaft and taper had any function. I don't think so and its existence is a mystery to me.

I had a project for a motor with a crank on (that is for a later posting here) so I cut the pump part off as shown below. That end face was milled flat for mounting.

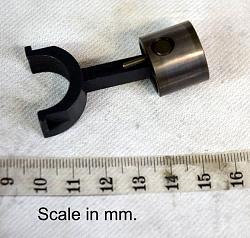

Here is the tiny piston and conrod. the piston and its cylinder are both made in grey cast iron and so are very much self lubricating. When I used this as a vacumn pump I never added any oil which is contrary to the advice given in the previous post. When I extracted the motor and removed the piston there was NO sign of any wear. The crank is also made in CI and there was no wear on that either.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks