I am also a member of the Yahoo Unimat group and have found this website very useful. I use Pinterest for discovering many tool ideas and have my own Pinterest pages for saving ideas for future projects. It is a great visual resource.

I am also a member of the Yahoo Unimat group and have found this website very useful. I use Pinterest for discovering many tool ideas and have my own Pinterest pages for saving ideas for future projects. It is a great visual resource.

Hemi (Jun 21, 2018)

Thanks, Paul Jones. I could not agree with you more. Some time ago, I had difficulty in locating a website that had seen before; now, every time I find a page which could be useful in the future, I simply save the link in Pinterest, so it will be easy to locate at any time.

Paul Jones (Jun 28, 2017)

A similar situation, just not guy down MY street.

I'd land on this thread periodically, among general return-on-search posts [lathe, indicator, milling, collets] and more specific searches ie ER collets. Not had or used mini-anything in ages; topics would soak in, but Unimat focus didn't pass "Ah yes, I remember" very far. Until last Sunday! I nearly tripped over my new-to-me mini. Typical scenario, garage sale w/ SO; drive by appraisal said no items of interest for me. Not anything even related to the trade. Overheard a side conversation of neighbors, the widow's "...some kind of machine". I figured a drill press, wood lathe, lapidary...Nope, not even close.

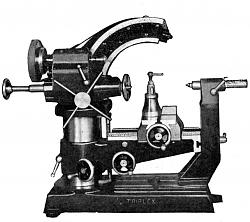

Count me in fellow mini-men. EMCO Compact 5, milling and all. Emco Compact 5 Lathe Husband absorbed an an estate, seems he wasn't a DIYer, in machining anyway.

Nearly identical, with threading; but no operator in a sweater. Pics have to wait. I'm packing for a 6 week contract gig in Nevada & auto maintenance for a 3200 mile round-trip.

Sincerely,

Toolmaker51

...we'll learn more by wandering than searching...

Paul Jones (Jun 28, 2017)

The closest thing I have ever owned remotely close to being a mini lathe was my first late the 9" South-bend 36" centers, the next closest was a 12 by 36" Craftsman / Atlas both only had a 1/2 or 3/4 Hp motor but could hardly be considered mini lathes. other than those I had my Do-more Versi-mill II which also had a 48" optional way bed with it I often used it as a lathe purely hand feed though with only a 3" movement for the cross slide. However I have often thought that I might want a modern mini lathe. This poses a problem fort me since the only mini lathes I have had any association with are the ones I've read about here on these and a few other forums, and the ones I have seen at Harbor freight or Northern Tools, they were what I would almost call shirt pocket lathes since they probably didn't' weigh much more than 75 lbs, but those for some reason don't really trip my trigger. I'm sure in their own right they are fine little machines I know several here seem to have made some amassing things with them. I'm looking for one in the 300 to 400 lb range and with the mill option upwards of 500 to 600 lbs. with at least a 1 hp motor with both metric and imperial threading

Never try to tell me it can't be done

When I have to paint I use KBS products

Paul Jones (Jun 28, 2017)

Good quality small lathes are fun to use for working on small parts. In college I work as a prototype machinist and did most of the machining of small parts on a well maintained Hardinge HLV-H lathe. It was the ultimate small lathe with a 11" swing over bed and 9" over carriage. Most of my work was machining mostly near the headstock so the 18" limit for the distance between centers was no problem. The lathe is normally setup with 5C collets but I used a set tru 3-jaw chuck. This lathe could machine extremely small and precise parts with tight tolerances. I wish I could afford owning a used one or one of the Hardinge HLV-H clones.

PJs (Feb 26, 2018)

hey Frank! Lathes one good example are the EMCO [not ENCO lol] #10'S. I'd warrant 99.9% of real combination mill & lathe machines are European, especially England German/ Swiss/ Italy, probably Spain. Those support their broad cottage industies, like Boy mini injection molding presses. The imported derisions we see and to remain unnamed [but feature a mill on headstock over spindle] have decent weight but are by most account huge POS; only thing they're good at. Not rigid, IMO don't what we'd call repeat, and those spiffy "Chinalectrics". Even choice of R8 spindle, short quill complicates holder changes. Another hard to find let alone search is the Hannifin Multi; I've only seen one. Supposedly they were on WWII US subs.

I'm off to Reno NV soon. So I started looking for what to come back with...one a genuine BC Ames Triplex basket case. Good thing, too heavy to lift into trunk.

youtube.com/watch?v=8bYNq3vZTPQ

Last edited by Toolmaker51; Jun 28, 2017 at 01:44 PM. Reason: stuff, always more stuff

Sincerely,

Toolmaker51

...we'll learn more by wandering than searching...

Paul Jones (Jun 28, 2017)

TM51, we'er getting ready for a road trip ourselves. We have to make a run up to Vashon island WA. to replace a hydraulic pump on a close friend's home elevator I built for him some 25 years ago. One would think if the pump lasted for 25 years it would last forever. Trying to decide if I want to pull an empty trailer or just take the chance that I won't find more than I can Beverly Hillbilly on my truck. I have my eye on a 46 Willis panel truck or a chushman truckster also 40 something vintage or I may just shove everything AI find in a 48ft dry van that I already have on the island and wait until my partner with his Mack can swing by and haul that back

Weight wise I could disassemble the truckster shove it in the willis and make some redneck ramps to push it up on the rails of the pickup bed. I'll have my wleder and torch anyway so fab work on site is possible LOL

Never try to tell me it can't be done

When I have to paint I use KBS products

Paul Jones (Jul 1, 2017)

Paul Jones (Feb 26, 2018), PJs (Feb 26, 2018)

Paul,

I just LOVE what ya done to your Unimat! MAN I'm droolin' over here......... IF only.......... I got 2 of the SL-1000's and one as a Lathe, and the other as a Mill as I do a LOT of model work with mine and some small stuff around the house so. those Mods to both of my machines would BE GREAT..... you got any "dimensions" of some of what you did? OR better yet, any way you can walk me through different DI's you done???????

I'm currently making a Lathe cross Slide "stop" for mine, as well as a bit holder for the Mill that will rest at the very bottom of the Head-Stock post of the mill, but thats simple items, the dials and all for measurements you added look as tho something I'd GREATLY use..... and would be a Unimat DRO (Just not "Digital") by sorts I guess..... Old School but WORKS!!!!!

Paul Jones (Jun 24, 2018)

Paul Jones (Mar 9, 2021)

There are currently 2 users browsing this thread. (1 members and 1 guests)

Bookmarks