Depends on size of Vee desired, small enough endmills are extraordinarily delicate. Many milling macines I've had access to aren't running well enough to utilize small cutters. Spindle, quill, and leadscrews need to be in good shape to provide 'feedback' that your senses use to control the operation.

In the post, offered alternatives that are reliable. Hack saw, band saw. circular blade, cutoff wheel, end mill...all applicable.

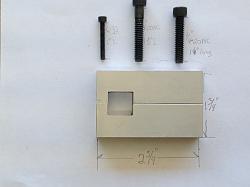

There are occasions where a endmill was used, after a saw cut to relieve load on a diminutive cutter. Two flutes probably better choice for chip clearance/ ejection as depth proportionately exceeds the width perhaps 3-4 times. A simple layout will illustrate size of sufficient relief in a specific Vee.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks