A while back marvklotz posted his "Lantern Vise" and I was stuck with how once again he had posted a very useful tool idea.

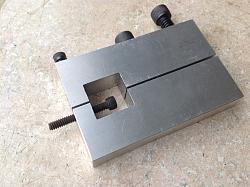

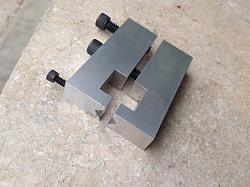

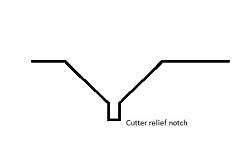

I'm using 80/20 extrusions for my main projects and am always having to modify the length of the 1/4" allenhead screws. Often just taking off 1/8" or less. This vise was just what I have been wishing for. I added the V cuts to the jaws and also the screw in the jaws so I could still grab really small screws. It also lays nicely on my mitre Gage on my metal bandsaw making the operation safe and easy. It also has come in handy for holding the screw head out to be able to grind heads for clearance. Another job I'm always having to do.

Thanks Marv

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks