With limited space my dust extractor lay in its box under my bench for 20years. My machines, excluding my RAS and 4' linisher, are on mobile stands to allow use by moving where there is space. I simply did not have enough overhead space for piping either. To avoid dust inhalation I would open two diagonally opposite access doors & roller door (or 2) and use the cross flow ventilation coupled with an industrial pedistal fan placed wherever it was needed according to breeze direction.

When I purchased a drum sander all that had to change as they HAVE to have extraction.:

So I planned and built this (version 2 which is stepped for height differences of the extractor (that had no wheels) & cyclone separater with drum. The rolling stand is made from used pallets : the only items I had to purchase were the braked rollers. My original drum, a 44 (Aus) gallon(200 litre) was too large to clear overhead timber & steel storage

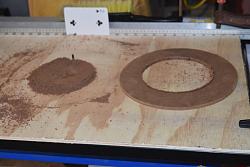

so I used one that I was using for fertilizer which did not have a flat top so I routed out a masonite ring and siliconed & bolted it to the drum lid.

The 200 litre one is now used for rock minerals for my garden/fruit trees & rain forrest regen projects.

I also envisaged more difficulty in emptying the large one as I get older & arthritis issues to boot.

I had to make a couple of conduit couplers for the cyclone & flexible pipe also.Not wanting to waste space I used the empty area for timber storage by screwing 2 milk crates (top one with bottom removed) to house 3' to 5' lengths.

Now I can roll the unit around to various machines after moving others aside.

Where there is a will there is an answer.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks