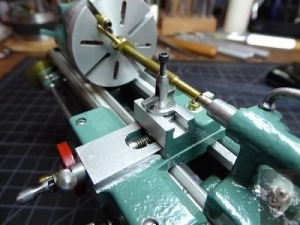

Ok, this is a bit of a joke but it took as long to make as if it were a practical size. It's a functional lantern tool post complete with rocker and bit ground with the proper angles to cut threads.

It was made to fit on my working dollhouse scale (1/12) metal lathe, made from a casting set obtained from PM Research. This picture shows it in place on the cross slide.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks