Hi folks

My next tool was going to be a dovetail cutter but I came across a tub of parts for a project I had squirreled away long before I had got my machines (I plan long term).

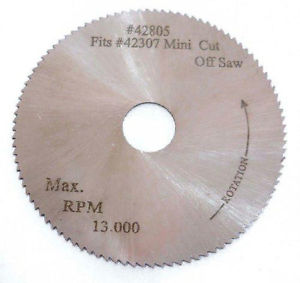

The part I was interested in most at this point, was the tiny 2" hss saw blade which had come from a mini hobby chop saw (the motor given out so I harvested the good bits). My blade has lost the writing on it from being used so here is a pic I got from tinterwebs of the same type of saw blade:

I have a lot of plans for mine but as I'm on a shop tool making spree right now, I thought I'd make a mini slitting saw arbour for it as one would be right handy for separating some T nuts I'm making.

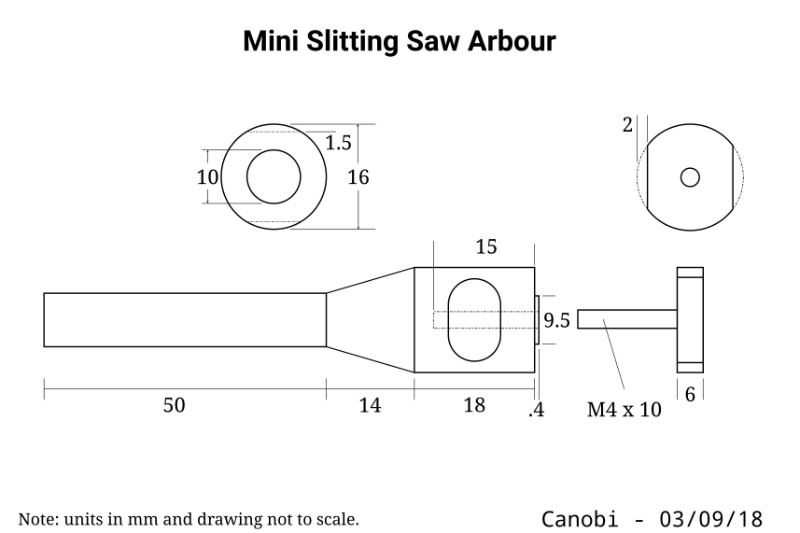

This time I decided to make a rough sketch of the arbour as a reference;

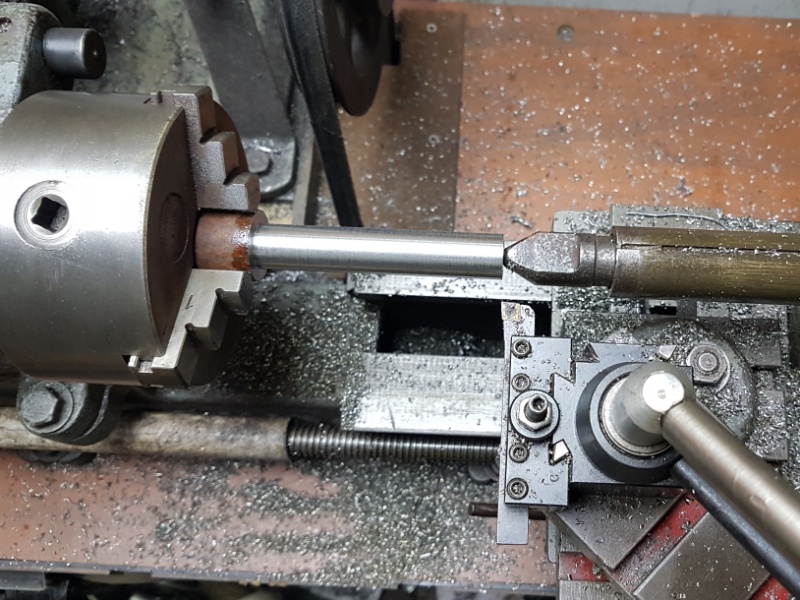

So with sketch on hand, the first task was to chop a length off of some 1" mystery metal bar stock. I chose to use this one as it turns really nicely and I can get a good shine on it after turning. I think it's a bright mild, no blue chips from it as I remember but they do turn a deep gold/straw:

Once I'd sliced off a piece, I chucked it up, faced it and drilled a centre hole for turning with a dead centre. Once that was done, I skimmed off a layer, took measurments and had at it till it was just over my chosen major dimention of 16mm:

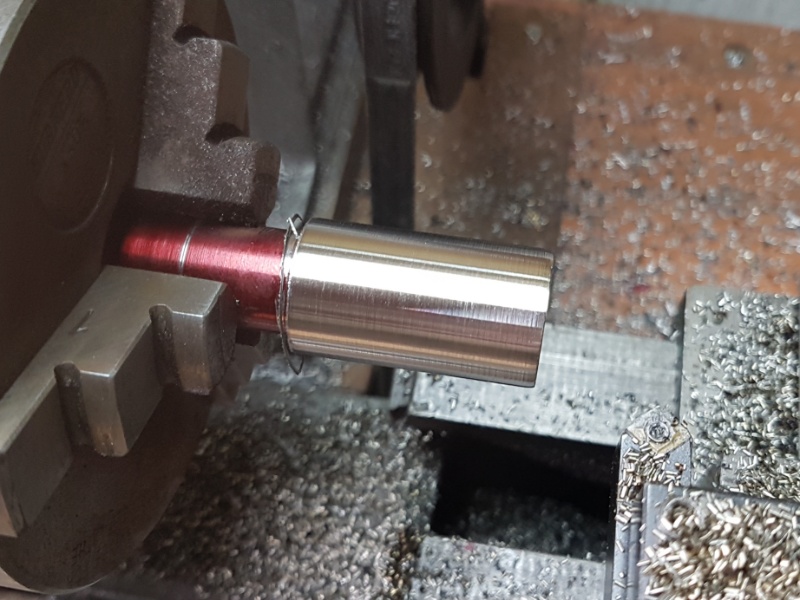

I then "blued" it for making my length marks and flipped it round to turn the other end down to size, closely followed by drilling and tapping the M4 hole:

I left the head of the arbour a bit long, in case I fluffed up the critical tolerances for the 9.5 x .4mm high raised bit that fits in the blade's bore, which I did but I managed to get it dead nuts on the second time round so I chamfered the hole, flipped it round again and finished turning the main shank of the arbour. I then gave the whole thing a sanding with some 350 grit and a buffing with some schotchbright:

Last task was to make the arbour's little clamp nut. For that I used the portion of the bar I had parted off just prior to facing the head to length. It was a pretty straightforward job so didn't think of taking WIP pics, my humblest apologies:

Still have to mill the flats and give it a polish but it's very nearly there

Thanks to all of you for the great tips, ideas and support, keep those chips flying and stay safe

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks