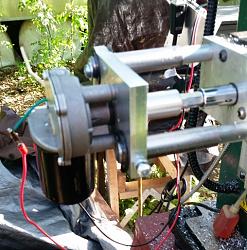

Here's a power feed that I made for my mini mill which was in my price range. The driving force is a Dodge Ram wiper motor. The motor plate on the left is pushed on guide pins to the right where the hex adapter on the motor shaft enters a deep socket on the right which is coupled to the table lead screw. The plate is pulled back to the left to disengage the drive and it's held in place by a ball detent at each position. This picture was taken before I finalized the control and wiring.

On a typical two speed wiper motor there are 3 brushes, the common brush, a low speed brush and a high speed brush. If the common brush is isolated from the case so that it isn't automatically connected to the power supply, then power may be applied between the low speed and high speed brushes, resulting in a third (and fastest) speed. I used a 6 position, 3 deck rotary switch so that I apply 12vdc power and polarity to appropriate brushes and I now have 3 switch selectable speeds in each direction, as well as a master switch to kill primary power to the 12vdc power supply that drives the motor. I added limit switches which disconnect motor power when the travel end is reached but still allow me to reverse in the opposite direction.

There's a brass shear pin which couples the hex adapter to the motor just in case, but I suspect that the plastic gears in the wiper motor actually protect the shear pin.

My surface finishes have improved, my fatigue levels are reduced and this was definitely a project worth doing.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks