For this project, I was inspired by a recently featured video:

Harbor Freight mini mill improvements - video

The crank is at about 2:44

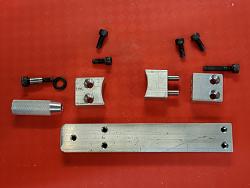

So, I designed and built a similar crank handle for my mini-mill fine downfeed knob. In the video, the clamp screw appears to bear on the knob itself. I preferred a moving jaw to avoid possible damage to the stock mini-mill knob.

I made the crank arm a little bit longer for better leverage and finer control.

Also, my crank is close to balanced. (If a crank has a "heavy end", that end may tend to rotate downward if not being held. Balancing reduces the likelihood that the crank will move on its own. This was only a minor design criterion.)

The moving jaw guide pins were made from 3/16" drill rod. The pins were pressed into the jaw and a close slip fit was machined into the piece holding the clamping screw. All pieces (except the hardware and the pins) were made from aluminum.

The knob on the mini mill is almost exactly 2" diameter. I cut the curve for the jaws using a boring head on my mill. (Ironically, I could really have used this crank during this operation.)

I turned the crank handle from aluminum rod on my mini-lathe.

The jaw clamp screw is metric M5-0.8 so that the hex keys I commonly use for the mill can be used to install the crank. All other fasteners are imperial #10-24.

(I did clean up some of the extrusion marks after the pictures were taken.)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks