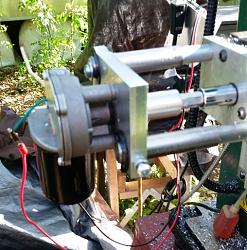

Finally I completed the assembly step of my power feed. I carried out this project without making any changes in the physical structure of the machine (hole, thread, weld, cut, etc.). I was able to install the automatic control using only scrap material. I will soon show you the mechanism in operation. If you are interested, be sure to follow my updates!

Support content creators, visit my page on Youtube!

https://www.youtube.com/channel/UCqw...E3eBi7w/videos

Thank you, M4A!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks