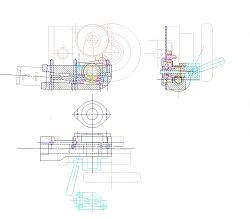

This is a variable speed feed drive I made for my old 7x10 that’s now on my 7x16. It kind of looks like what’s on some Hardinges but is smaller and cruder and only works in one axis.

Like the Hardinge apron feed it’s powered by a dc gearmotor and works using the hand feed rack instead of the lead screw. It has two speed ranges, I think up to only 3 or 4 ipm, I bought a faster motor to improve this but haven’t installed it yet. It engages with a lever operated cone clutch which I can set to slip when the carriage hits a bed stop.

It works pretty well and is strong and easy to use but without cross feed isn’t very practical compared with straight forward lead screw drives like Varmint Al’s ultra-fine power feed and jjr2001’s slow speed feed for the mini lathe, or even some kind of stand-alone stepper or servo-driven synchronized system like John Dammeyer’s “Electronic Lead Screw”, and different similarly named, mostly Arduino controlled projects based on the same principles. The modified apron probably has twice as many bearings and gears as the rest of the lathe.

I used a 500 rpm gearmotor, a 2-speed planetary transmission from an electric screwdriver and a 20:1 worm gear, with a couple of gears to mesh with the regular handwheel drive.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote PJ

PJ

Bookmarks