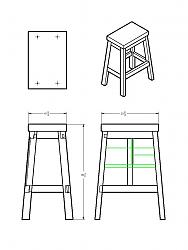

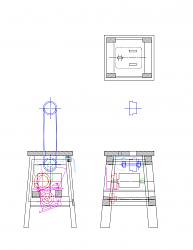

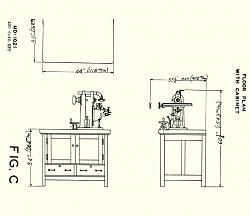

This is a stand I made for my small Atlas milling machine to replace a much bigger table. It has about the same footprint as cabinets originally sold by the manufacturer but is taller than those.

Like the Atlas stands it allows close access to the machine from the sides as well as the back, but it doesn’t catch chips and cutting fluid like ones with chip pans, or even the old table. The left side is open, but I plan to add drawers instead of a shelf.

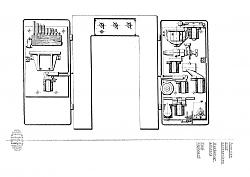

There are more practical substitutes for the sought-after originals - for example VSAncona built a nice version of the older lab-style hardwood stands from Atlas, and Ruxu modified a tool cabinet to make a neat base for a heavier mill-drill. There are many more.

Mine probably could be a couple inches lower, which would still put the spindle and handles a lot higher than what seems to have been standard eighty years ago - I just copied the height from the old table which was alright to use. It could be heavier, too: it only weighs half as much as the wooden Atlas stands.

Construction is pretty much the same as my lathe bench, and like with it I used mostly recycled materials. The 3-ply top is edged with oak and covered with formica left over from making that.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks