Hi,

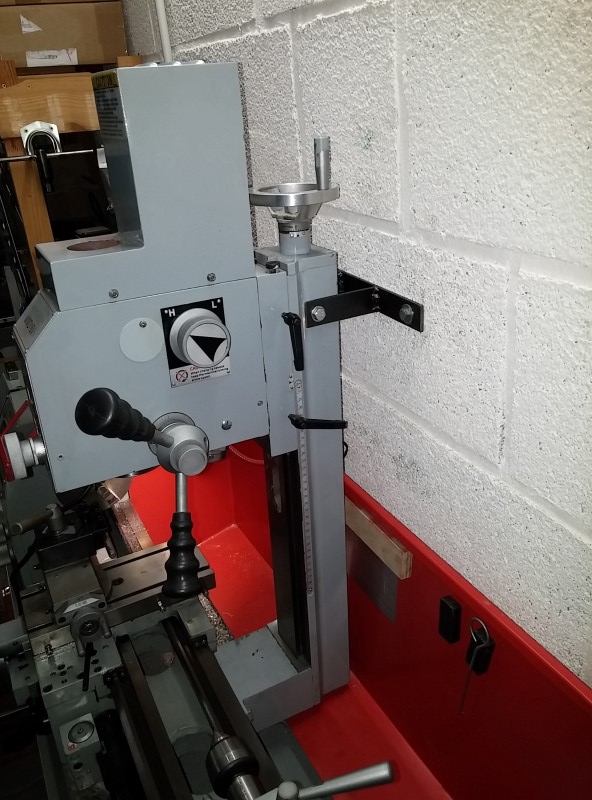

As I said, I have purchased a nice milling head that goes together with my lathe.

This lathe is Chinese made, sold by a company from Austria which is quite OK.

When I installed the milling head, I found the attachment between the column of the mill and the bed of the lathe as a weak point.

It is made of only 4 screws, not locking very well the column in rotation.

I was looking at the best way to improve that in order to avoid any rigidity issue. I was about to install some screws in the joint between the column and the bed, to avoid any relative movement when suddenly, the light came !

Eventually, I finished with this solution :

It could not be stronger nor stiffer !

Of course, I made oval holes, and used a digital angle gauge to set the column perfectly perpendicular to the bed before tightening the screws on the wall.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks