This idea came to me when I had to make repeated small increments to the depth of milling a part. The wheel is an inexpensive steering wheel from a power boat, found in any boating/marine/ship chandlers shop. The rim of the wheel is always just at hand, rather than fumbling for the crank and if you chose a steering wheel of larger radius than the crank handle (normally supplied with a small mill) very small height adjustments to the mill table are much easier to make. In addition it's also easier to lift the table with minimum effort when its loaded up.

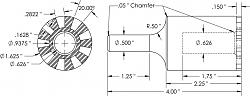

The solution for attaching the wheel to the square shaft on the mill is to made the female part in two halves, and to fasten it with a simple knob which forces the halves together onto the shaft.

I hope the photos show all that you'll need to make one for yourself.

Feel free to email me if you need further explanation. All the dimensions and way you proceed will depend on the materials you have at hand and the size of your mill, and sorry I don't have any drawings.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks