Hi folks

Last summer I was lucky enough to score this lovely little J&S boring head that takes 3/8" boring bars on ebay, so I bought a few lengths of CoHSS to go with it so I could grind my own set but that's a job for the future as I don't have a tool and cutter grinder just yet.

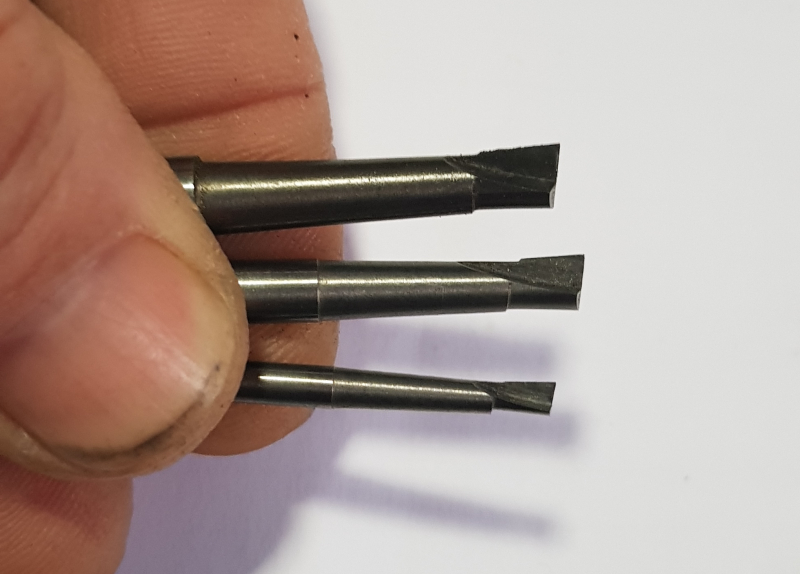

Time passed and just recently I find out that a set of what I thought were single flute milling cutters that came with my mill, were in fact micro carbide boring bars.

They're pretty small, the shank diameters are 1/8",3/16" and 1/4" but I figured I would make some adaptor sleeves for them so I can use them in the boring head.

For the boring head sleeves I acquired a length of 3/8" silver steel as it comes ground to size. I started with the 1/4" and simply centre drilled and reamed the hole to size.

Once the turning was done, I used one of my toolpost holders as an impromptu mini vertical milling slide and milled a slot into the side of the sleeve so that the boring head grub screw passes all the way through the sleeve to clamp the carbide bar directly and once the slot was deburred, it was ready for use.

I then turned to the 3/16" but this time I opted to do a little eccentric turning. First the hole was drilled and reamed off centre by approx 1/16",afterward I turned the shank coller while still in the off centre position (I don't do much eccentric work so any excuse for practice and removing some material from around the shank will give the tool a bit of clearance). After the turning work was done, I repeated the milling step with the first one and deburred it to finish the part.

Last but not least, was the 1/8". Again, I chose the eccentric option and repeated the operations as before but this time the offset was closer to 1/8" from centre. Since there was enough meat on one side to fit a small grub screw, so I chose that option instead as the required slot width to fit the boring head grub screw would have been too big in this case.

Well, now I've made some adaptors for the boring head, I think I'll make some for the lathe too...

Thanks for looking

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks