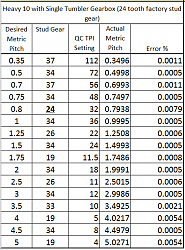

I figured out a way to make perfectly acceptable (Something above 99.5% accurate) metric threads on an old South Bend lathe, just by making a series of 5 different stud gears. The idea should work for almost any imperial lathe. The required gears may vary some from lathe to lathe, the attached Excel spreadsheet can help you figure out your own.

See the video for details.

The Excel spreadsheet is designed to simply display the resulting metric thread for every possible combination of stud gear size and gearbox setting. You simply visually find which stud gear and gearbox combination will produce the closest approximation to your desired metric thread. In my case I was able to make a set of 5 replacement stud gears that could produce all the common metric bolts, from the tiny .35M up to the large 5M, all with above 99.5% accuracy to the desired thread. (Most with above 99.9% accuracy)

The only variables for your lathe are, "what is your "native" stud gear size?", and "what exact tpi settings are available on your QC gearbox?" Enter those in the spreadsheet and it will display the rest for you.

stud gear metric settings.xls

Here is the resulting chart for my "single tumbler" South Bend lathe:

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks