Another one of my "not exactly a tool" but more of a "how to use the tools you already have". Nevertheless, I think the idea is sufficiently "toolish" to belong in the homemade tool forum.

Many hobby machinists have 1-2-3 blocks. They're often used as spacers and supports but it's less often that they are used as measuring tools. Here I discuss such a use.

Everyone knows that to measure a taper, one needs to measure the diameter at two points separated by a precisely known distance. The exact separation is not important but it must be known precisely to produce precise results. Many taper standards exist and often the differences are tiny so precise measurement is important in order to distinguish between similar tapers.

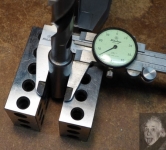

Support the taper vertically (in the photos I propped the drill against one of my height gages) and lay a 1-2-3 block on each side with the 1" dimension vertical. Lay your calipers on the blocks and close them against the taper. Record the caliper measurement as D1. In the photo below, my caliper is reading D1 = 0.614" against a taper known to me to be a Morse #2.

Now repeat the procedure but this time lay the blocks so the 2" dimension is vertical. Here my caliper is reading D2 = 0.664".

We now have two diameter measurements separated by precisely one inch. The taper is then calculated as:

Taper (in/in) = (D2 - D1) / 1 = (0.664 - 0.614) / 1 = 0.05 in/in

If you look up the spec for a MT2 in your references, you'll find that it's..., wait for it... 0.050 in/in.

There are other ways to do this, of course. You could build an attachment to mount your calipers on a height gage and use the latter to establish the measurement separation or mount the calipers to a lathe carriage fitted with a DRO and hold the taper to be measured in the lathe chuck.

But I prefer my approach. It's simple and requires a minimum of equipment. Plus, it provides a satisfying opportunity to use one of the most under-used tools in the shop, 1-2-3 blocks.

Of course, this technique requires blocks that are on size. Check yours before using. Even if they're not precisely on-size, the technique can be used but you'll need to calculate the actual separation between the two measurements.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks