It is always a problem when you have no surface and no place for a common tool like a kaliper or a depth caliper.

Then last week when I have three particular pieces to modify, changing the Schaublin 38mm. thread by a M40X3 with an insert, and a result which does be in less than a tenth millimeter error, I find the solution with that tool, it's easy to understand how it works, you can use it with a micrometer or just with the moving piece.

You take the measurement in the tool with a classical caliper, and use the micrometer next to make the finish, or you can adjust the micrometer on somethig like a bearing and use it like a normal micrometer.

I hope my explanations are not too hard to understand and will be happy if that can solve a problem for you.

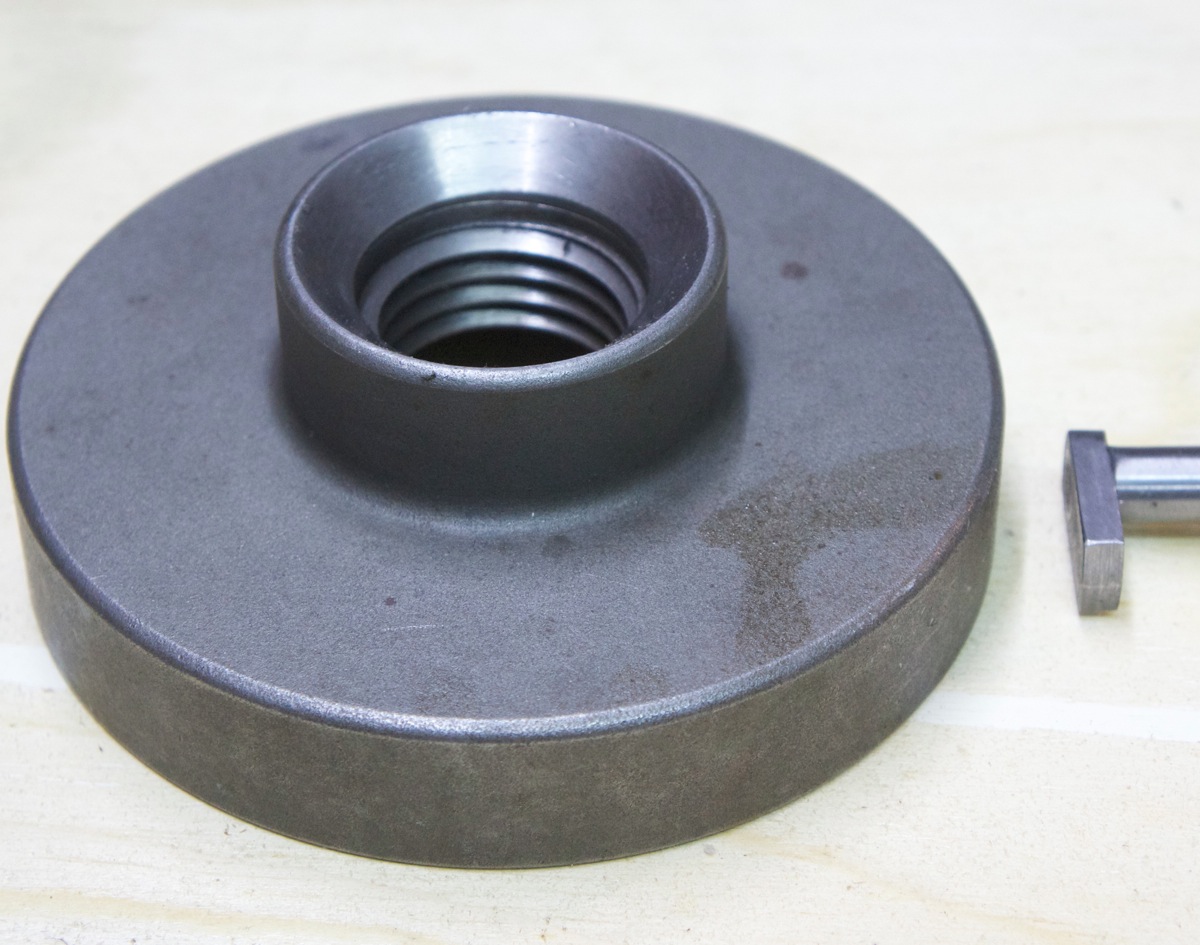

One of the pieces i modify.

The inside view.

And the new tool.

On the lathe.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks