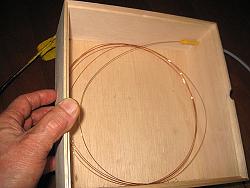

Things I mostly enjoy TIG welding are small engine parts like power pipes, carburetor attachments and etc. made from mostly 0.5mm thick steel sheet. The parent material of this thickness needs small wire, 0.6mm in diameter as far as my welding skill concern but this wire mostly come to us wraped on a round plastic reel so that they get curly or curved when released from the reel. This causes me trouble in trying to give the part some precision work, so I had to hold the wire as close as possible to the aiming melting pool with the other hand.

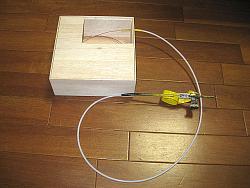

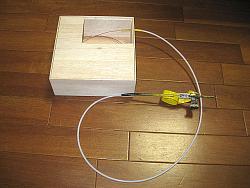

This manual wire feeder helps me a lot in this sort of precision works.

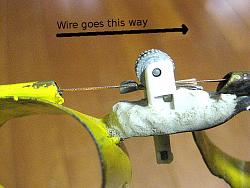

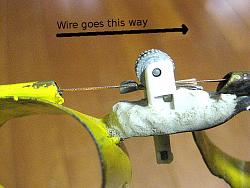

The only one mechanism came from a used disposable cigarette lighter, using the round file that makes small sparks to light the gas. Remove the lighting stone out but use the spring inside. Add a small plate, cut in a right shape to fit in, so as the spring pushes this plate upward to press the wire on to the round file above.

One tip for smoother movement is that you should better use a Teflon tube for the lead part between this reservoir box and the feeder. I tried another material but was not very good though.

[ATTACH=CONFIG]23103[ATTACH]

Chy

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks