Hi All

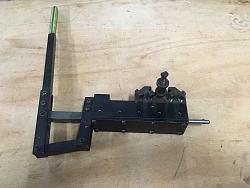

I made this simple manual slotting/broaching attachment for my lathe. I do have a set of imperial keyway broaches but the set only has 5 sizes. As broaches are so expensive and this is afterall only a hobby I can't justify buying every size I need. The cost and the amount of times I would use each broach and often to only cut one keyway. I decided to make this tool so I could cut anysize by grinding a piece of high speed steel to the desired size.

The tool has a 3" stroke and the material costs were half the price of one good quality broach. I kept the build construction very simply by using a solid square stock bar as a ram with a simple lever operated movement to drive the tool in and out.

The other advantage of this tool is blind holes can also have keyways cut, I normally drill a cross hole or undercut the bottom of the hole to prevent a build up of swarf at the end of the stroke.

The ram is held in place with two Jibs/Wear plates so the tool is ridged but can still slide smoothly with little friction/resistance.

Manual slotting tool

Lever mechanism.

Made to fit standard lathe tool holder.

In place on the lathe with the ram fully back.

Fully forward (total tool movement 75mm / 3")

Different tool holders can be clamped to the ram.

Jib/Wear plates can be seen top and to the left of the main ram. The plates are adjusted by grub screws to prevent lateral side movement while cutting.

This didn't take long to make but has saved me hundreds of pounds in tooling.

Thank you for taking the time to read.

The Home Engineer

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks