For many years now I have had a set up for dividing the lathe headstock for drilling, milling etc, using a live tool post spindle.

Unfortunately this has always involved a rather tedious and messy set up i.e. removing all the change gears, taking off the guards, reversing the banjo, etc.

Myford Super 7 owners are lucky to have a 60 tooth bull wheel for use but not so for my SouthBend.

The trouble has always been finding an alternative solid mounting point for my 60-1 dividing attachment mounted in the usual place at the end of the mandrel (I have ground the bore of which true for 4 inches as this is a drilled item and is rarely concentric). The alternative would be to locate the gear by the machined o/d of the mandrel end.

While removing the tumbler reverse gear assembly one day for cleaning, the light bulb in my head came on as I was looking at the perfect place, a solid hole in the head stock begging to be used for this.

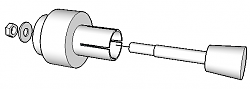

A M/S expanding mandrel was soon made to fit said hole.

Now after removing one bolt and slipping out the tumbler I can now leave all the change gears in place while I fit the dividing set up in a few minutes, I am now much more inclined to use it and as a bonus it is more rigid than the original set up. The whole assembly is a bit on the rugged side as it doubles with my table dividing head.

I hope this is of some use to anyone who is lucky enough to own one of these lathes but the idea may be adaptable to other machines.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks