There are two items I am missing in your design: It is not adjustable, and it doesn't have a fence.

For a once-off job, being adjustable is, of course, not a issue. And if you are planning to bend several items, without a fence repeatability will be poor.

This is what I learned after building this

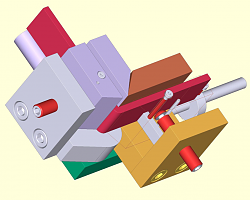

following a suggestion found on this forum a few weeks ago, a three pin design very much like your own. Since I had to bend flat bar 6x32mm, instead of the pins I used pieces of 20mm plate, held in place by M10 bolts. The angle plate on the left is adjustable, and that is where my design failed: the three M10 bolts are not capable of holding the angle in place, and thus the bend is not as sharp and neat as I wanted it. Even though the high-tensile bolts have been tightened until the 20mm plate got (locally) deformed, the friction forces they do apply are not high enough, and slippage does occur - and thus the bend is no longer sharp.

There is a solution, however, as exampled by tuomas

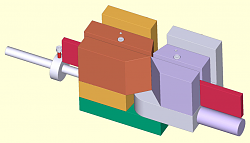

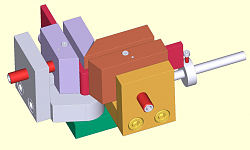

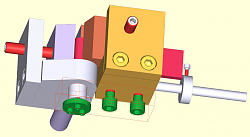

Vise bending attachment: Instead of three pins use two vises, joined by a hinge. When closed loosely, these vises ought to give just the control over pin spacing that I need to give me the sharp bend that I want.

For the vises, I will follow closely this design, used here on a rotating table:

. Essentially, a M12 grubscrew has been grooved such that a 3mm roll pin connects it to the moving jaw, without blocking its ability to rotate freely.

My fence is just an afterthought; it works just as well as any more fancy machining could have given me.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks