There are times when the exact size skip bolt or shoulder bolts simply do no exist off the shelf or if they do they are special order.

For a project I am working on I don't need precision ground and hardened bolts but I do need a shoulder.

There are a few ways to accomplish this 1 would be to start from scratch with a piece of hex stock then machine out the bolt as required.

Another way would be to slide a length of tubing over the bolt which in my case would have worked just fine, but I opted for a third way

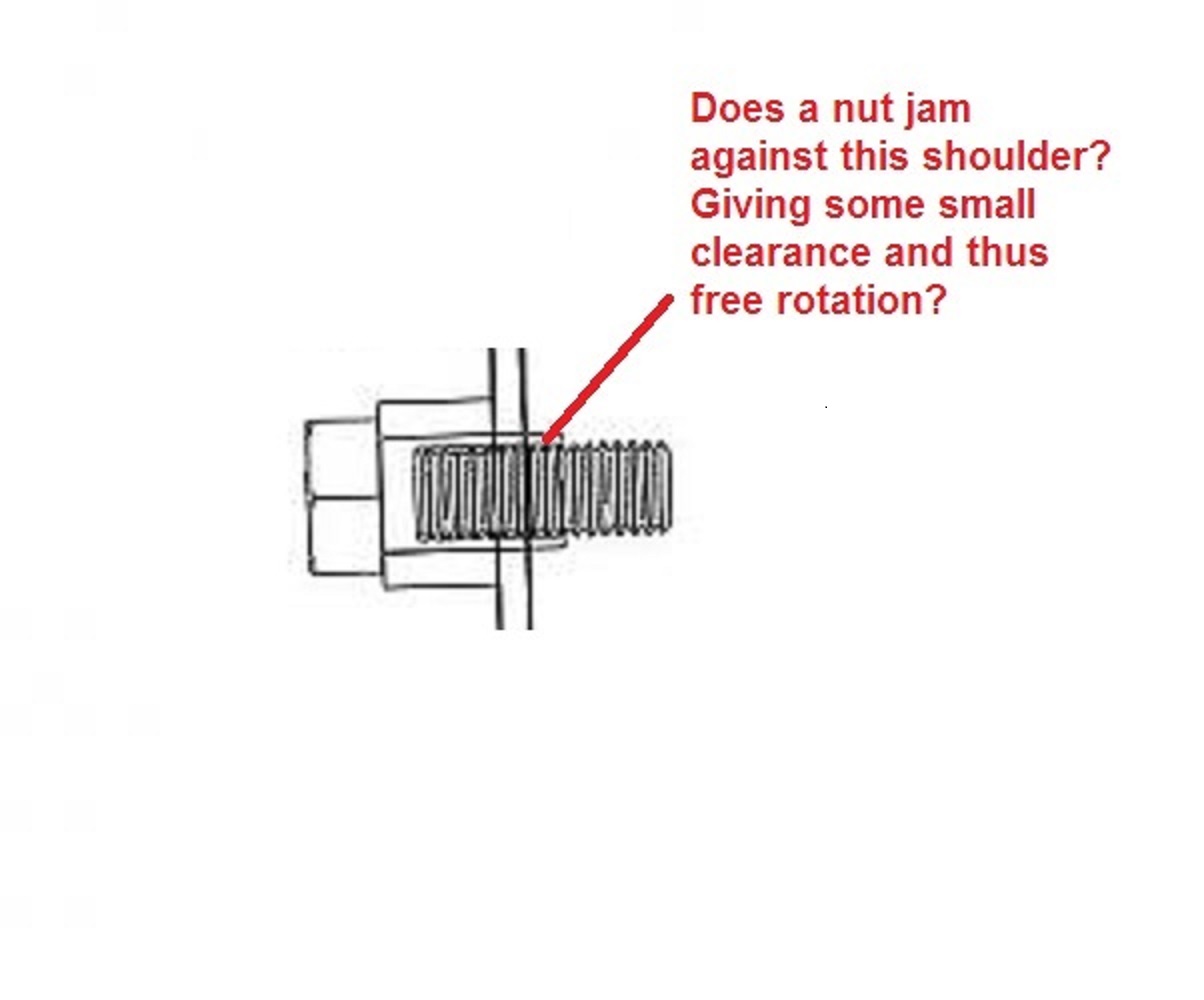

By drill and taping a piece of round stock turning to desired length then screwing it onto the bolt.

I purposefully drilled 1 size over size to make the taping easier

I also turned a step on the nut for locating it in the hole

The shoulder on the bolt protrudes beyond the wheel mounting plate to lock against the nut welded into the member

the trolley truck is free to rotate about the shoulder

while the shoulder being tightened against the nut and centered to the hole side ways stresses and movement is all but eliminated

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks