In the days before I treated myself to a nice set of Wiha nut drivers, I needed a slim profile nut driver for mounting some thread lock 2-56 nuts on a model engine. There was no clearance to use a wrench and the thread lock feature meant more than average torque was required to seat them; a nut driver was the only practical solution.

I happened to have some stainless shoulder bolts that took a 1/8" AF Allen wrench and the 2-56 nuts were also 1/8" AF. I threaded a stainless rod handle to match the 10-32 thread on the shoulder bolt and Loctited the bolt into the handle. Then the bolt head was turned down to a profile that would allow the nut driver to work in the available access area.

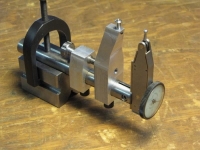

This photo shows the shoulder bolt on the left and the nut driver business end on the right. Front center is a 2-56 bolt with one of the nuts.

Here's another photo showing a side view of the components.

Of course, forging your own hex holes can be done but reworking a SHCS or similar is generally a lot easier for the novice machinist.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks