Hi All!

I'm making a folding tripod using 1x3 triangle as legs. legs will unfold around a steel tube when set up. When not the legs will fold flat-ish.

There are two pairs of hinges on each side of the middle leg on top and bottom; think a M or W where the other two legs can swing in & out

I need through-bolts since wood screws won't work, but the hex nuts would interfere when closed, so

counter sink nuts! :-)

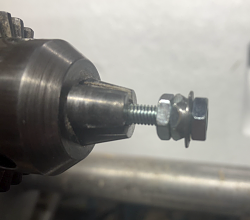

I chucked a 10-32 screw into my trusty ShopSmith 10-ER, jammed a couple of nuts close to the end, a washer, then the soon-to-be-conical nut last

The middle nut suffered on the 1st attempt, hence the washer. So

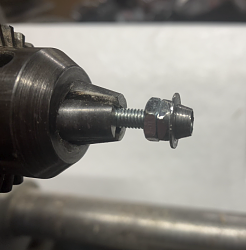

The washer is quite handy as a file guide, and a way to unscrew the cone. Here's the result

Yes McMaster has counter sink nuts; at US$13 a pop

Enjoy!

Doug

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks