"I am not sure what you mean by a roll in saw. Maybe I know it under a different name or maybe I just don't know it?" quite possibly.

Here are some pictures of a saw like I had and judging by the back ground it may even be my old saw.

The table is stationary the work piece remains fixed to the table while the saw rolls into the cut, the saw can be tilted right or left up to a 45° angle. the entire body of the saw rolls into the cut this can be done manually or by a powered feed

Never try to tell me it can't be done

When I have to paint I use KBS products

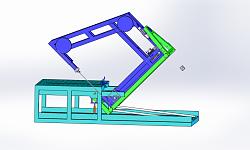

Here are some Jpegs of my drawings of a large sandwich panel cutting saw I made while in the Middle east.Sadly unless I can get someone to help with data recovery I have lost almost my entire collection of 35 years worth of photos Pretty much every thing prior to 2013 is lost, But fortunately I kept my engineering and drawing files intact.

This saw was made to cut steel clad foam filled sandwich panels or stacks of them up to 600 mm thick. it had a 1500 mm travel could be tilted 45° either direction. or the blade guides could be rotated 90° for linear cuts the saw could also be locked in position and raised to make bevel cuts linearly as well

Never try to tell me it can't be done

When I have to paint I use KBS products

Jon (Feb 14, 2018), KustomsbyKent (Feb 13, 2018), mwmkravchenko (Feb 13, 2018), Paul Jones (Jun 13, 2018), PJs (Feb 14, 2018), tonyfoale (Feb 15, 2018)

That is a serious bit of kit. I didn't realise that DoAll was the name.

I like your panel cutting saw, especially the two axis tilting mechanism.

Both of those saws make my new one look like a tiny toy. I found an hour today to get more work done on it, most of the fiddly stuff is done now so completion shouldn't be too far away.

Yep it was a serious saw. I modeled my panel cutting saw sort of after the Doall design but as always I had to Frankinize it I primarily made it for a 110,000 cubic Meter frozen food storage building we contracted to build but we also used ti to cut 300x600 mm Steel beams with until we got our Chinese 15 HP twin column horizontal band saw talk about a serious saw the wheels were 900 mm in diameter, the blade was 55 mm x 2 mm by 10 meters it could make cuts through solid ba up to 1200 mm by 700 mm if you could find one that big, or the saw could rotate to 45° and still cut 900 mm by 700 mm

Never try to tell me it can't be done

When I have to paint I use KBS products

To make sure I get the blade speed of the bandsaw:

If the rpm of the motor is, say, 1000, then in one minute the drive wheel achieves 1000*2r*pi. The bandsaw wheel circumference is 2r'*pi, thus the bandsaw wheel achieves 1000*2r*pi/2r'*pi and the blade travels (1000*2r*pi/2r'*pi)/blade length.

Corrections gratefully received.

Neil,

Firstly, bandsaw wheels are rarely if ever driven at motor speed so you need to use wheel RPM not motor RPM. I don't follow your logic in cancelling out 2*pi and I don't understand the two radii, viz: r and r'. There is only one wheel radius of interest.

So the wheel circumferential speed is RPMw*2*pi*r where RPMw and r refer to the wheel. That is your blade speed in the units of r per minute or RPM*pi*r/30 if you want it in units of r per second.

If you want to relate that to motor RPM you need to divide by the motor to wheel gear ratio, GR.

So now you have RPMm*2*pi*r/GR or RPMm*pi*r/(GR*30). where RPMm is motor RPM.

The blade length has no influence on blade speed but it does affect how often the blade "rotates", if we call that RPMb then RPMb=blade_speed/blade_length or RPMb=RPMm*2*pi*r/(GR*blade_length) or RPMb=RPMm*pi*r/(GR*30*blade_length) depending on whether you want it in per min or per sec.

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks