Hi Everyone! I wanted to show off our "Maker's Vise" here for our kickstarter launch. My boss and I set out to design a greaseless vise for our own use. We do a lot of prototype work which often requires designing our own tools. And, grease is a contamination for the silicone encapsulation work that we were doing. After we began building our first vise prototype, it became apparent that this is a tool that could replace most of the vises in our shop.

The main ideas:

We redesigned the toolmaker style of vise to be a general purpose vise.

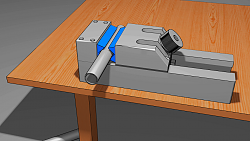

The maker's vise concept drawing [holding conduit]:

The slide surfaces are made from Delrin. I would describe Delrin as a plastic similar to Teflon, but more durable and better under compression.

Unlike the toolmaker style vises, the maker's vise counter-brace (the part that makes it a vise) is self-aligning. So, you can just slide the head into position and apply torque to the knob handle. Use a hex key for up to 1500 lbs of compression strength.

We are also advocating for the use of 3d printed custom jaws. People have been making custom jaws for a while. Generally by cutting a makeshift piece out of wood. But, that's the old way of doing things. Modern multi-material makers benefit from the miracle of plastics. Custom jaws can be printed exact to fit, reducing the overall clamp force needed and risk of damage to your project.

We are crowdfunding for tooling and to do our first production run! Here is a picture of our current prototype:

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks