Hi All

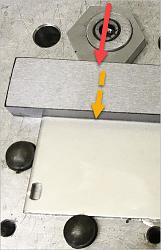

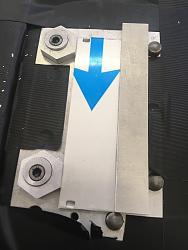

Yesterday I made some low-level edge clamps from aluminium for the CNC engraver at work to fit a jig plate. As the stock material is small makes it difficult to hold on the machine, as it is fitted with a vacuum table. The components need both, engraved text and holes the manufacturing process is to be, completed in two operations text then holes to save tool changing. Therefore, repeatability is required to ensure everything lines up.

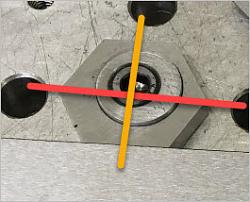

The threaded cam has a 2mm throw and a M6 cap head press fitted. The main clamp is 25mm A/F. The counter bored holes are, offset to give different clamping distances when used on the jig plate.

The clamps simply push the work piece against the datum pins on the jig plate to lock in place.

Thank you for viewing

The Home Engineer

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks