Hi,

I bought some time ago some heavy M20 threaded rods and nuts and washers with the idea to make myself a kind of press, but I gave up with this idea and I was left with these screws and nuts I had already purchased.

I have been wondering for a while what I could do with them, and I came up with this :

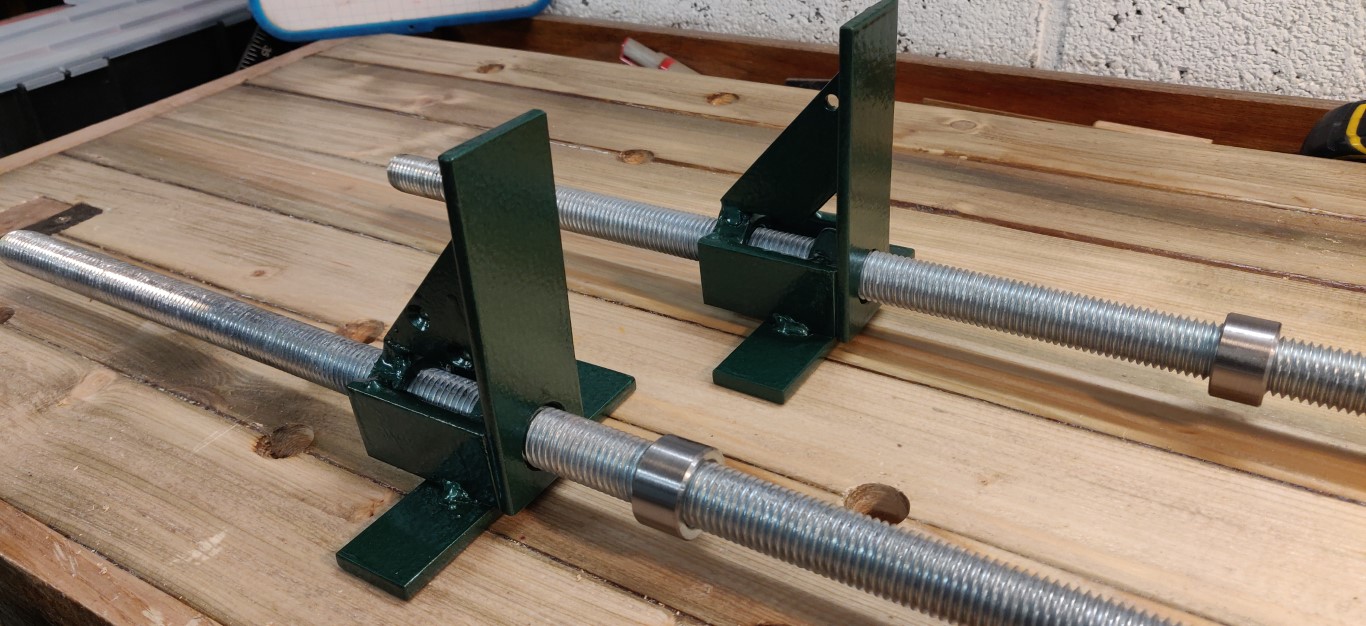

A pair of long parallel clamps, a little bit like pipe clamps, but they are just screw clamps

It's just an assembly of the screws and nuts, some scrap flat iron, with the addition of some turning and welding and painting.

OK I already know, no need to tell me, it's not the best idea for wood projects, the threads can mar the wood and leave marks on it.

Anyway, I had the material, It will be useful sooner or later.

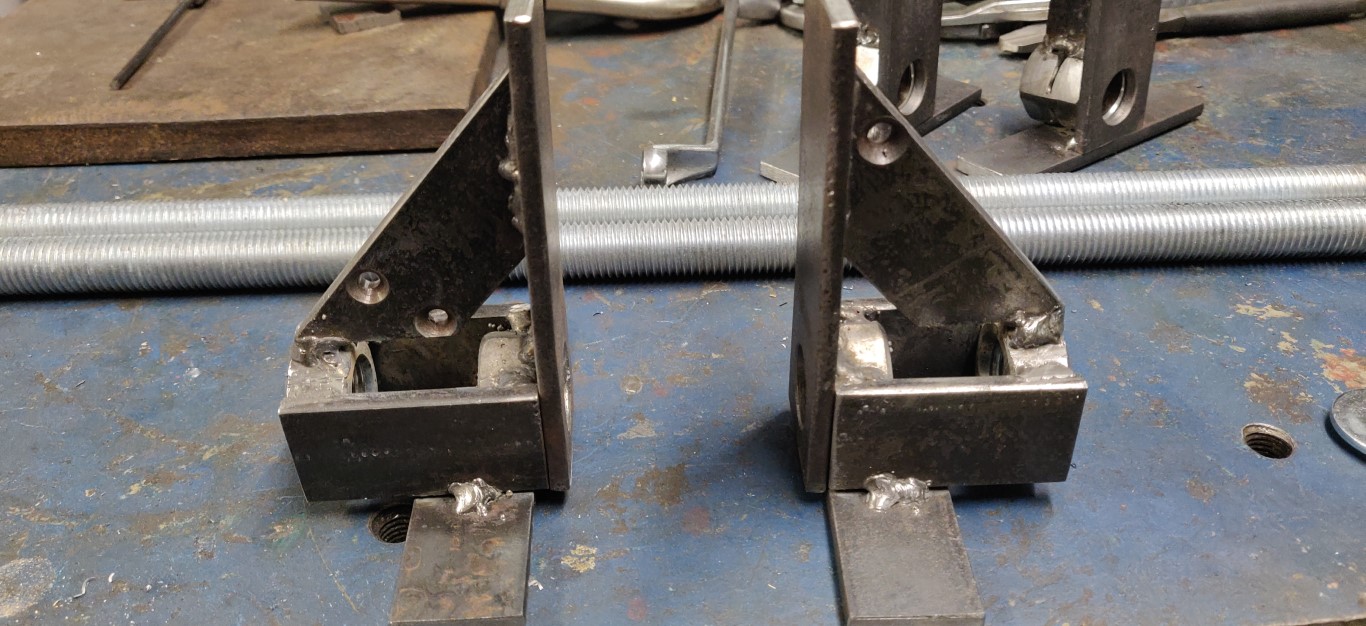

So I just improvised a setup with scrap flat pieces of steel and welded that all together.

Well, I must admit that my talent as a welder is very limited, but all in all, I think it will be strong enough.

Here are the parts :

The mobile jaws, made with a couple of nuts, a vertical flat jaw, a brace on its back, two cheeks and a sole :

The fixed Jaw, still a couple of M20 nuts, but the inner threads are removed on the lathe, the inside is bored to 20mm :

In order to have the screw freely spinning in the fixed jaw, the threads are kind of replaced by a brass sleeve shown on the following picture.

This part of the screw is also turned down to a 17mm diameter and the threads are replaced by the brass sleeve ID 17mm, OD 20mm.

In addition, two M20 nuts are turned round on the OD to make spacers so that the work-piece does not touch the threads of the screws.

One of these rings is pinned in place against the fixed jaw.

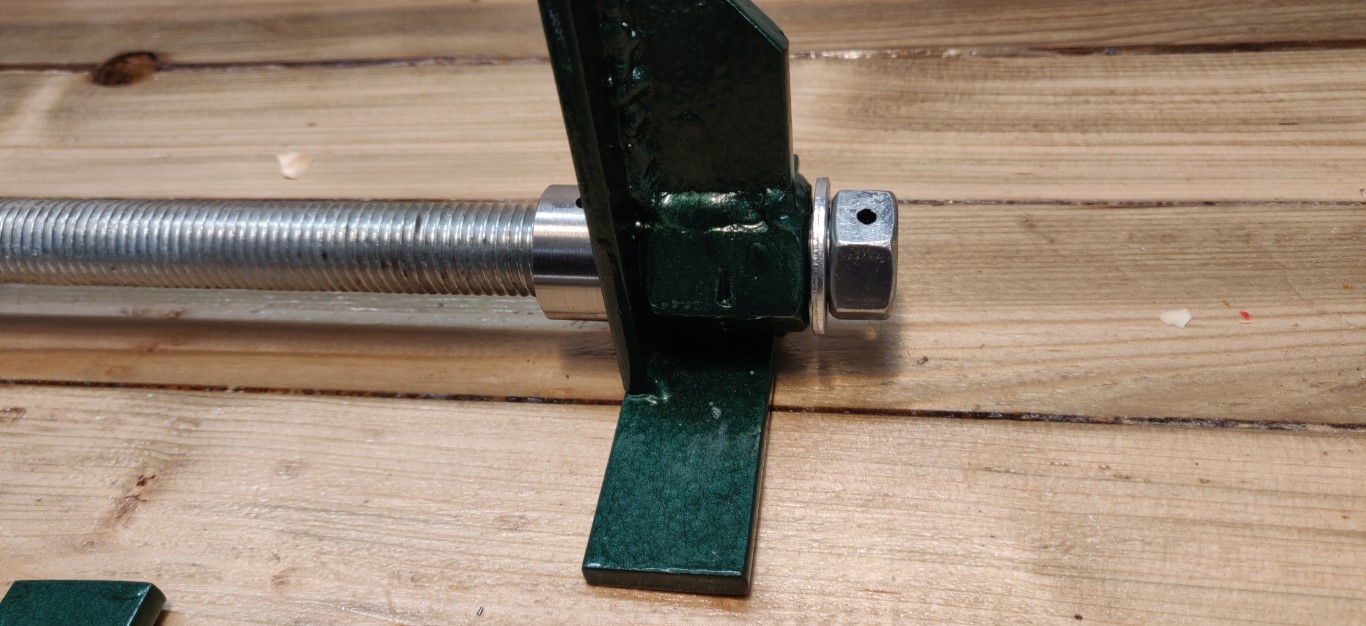

On the other side of the jaw, the screw is operated using an M16 nut, wiith its threads removed and turned on the lathe to a 17mm ID.

The M16 nut is pinned at the end of the screw and is used to operate the screw.

(No room for a crank, I want the clamp to be able to sit flat on the bench or the ground.

So here is the final product :

It's basically operated using a rachet with a 24mm socket.

In order to speed up the operation, I can still use the electric screw driver:

Example of use :

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks