Hi folks

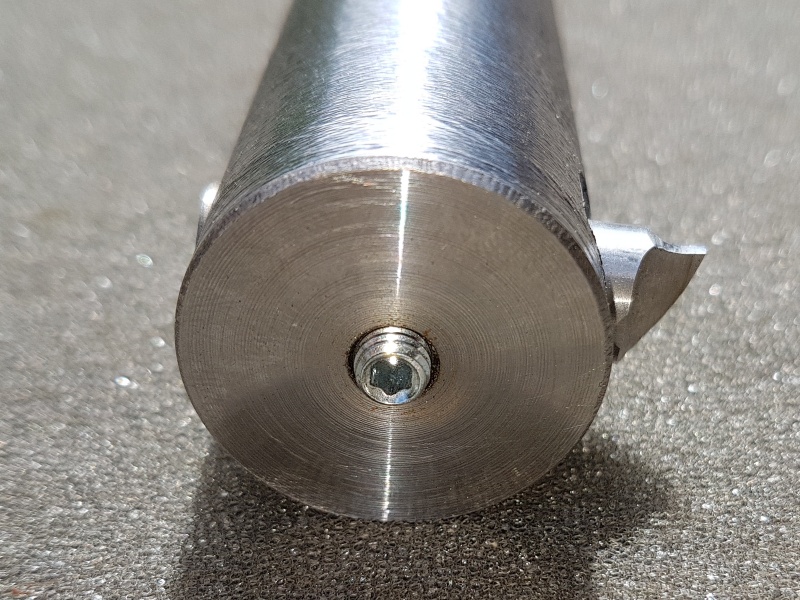

So my workshop is finally equipped enough to get a start on making the things I put it together for. Unfortunately, my small lathe's toolpost won't take boring bars with the kind of girth I'd like, so I opted to make a long boring head I can use in my ER32 collet chucks:

The head is nothing special and was a simple turning job, though the finish on the head might make one or two of you wince a little but was done on purpose for artistic flair. I'veworks copper and did a fair amount of smithing in my youth and surface texture has always been an interest of mine. It occured to me while turning the head that it wasn't a critical surface so thought I'd see what controlled chatter could do. Though it's a bit uneven as I was testing it out for the first time.

Canobi

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks