I really dislike repetitive measuring when there is a way around it.

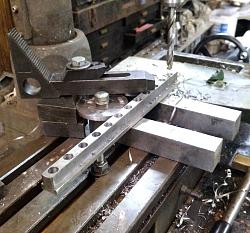

For drilling a series of holes in a straight line on my mill or in a drill press for that matter I like to make a stud pin hole locator.

For my T nut project what I did was machined off the head of a 1/2" bolt then turned the OD of the end of it down to match the ID of the holes in this case 27/64s

Loosely mount it in the table slot

Center the drill chuck over it snug up the chuck and tighten the stud pin in the table loosen off the chuck and shift the table the proscribed distance to where the next hole would be lock down the table and start drilling

Advancing the bar one hole at a time the standoffs position the bar in the Y plane while the pin stud positions in in the X plane until I have advanced as far as I can still clamp the bar

Then I remove the stud pin flip the bar around use the drill bit to locate the last hole drilled re locate the stud pin under a hole in the opposite end of the bar then drill the remaining holes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks