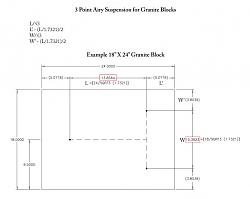

For minimum deflection, the plate should be supported at the Airy points. These are two points spaced a distance apart that is the length of the plate divided by the square root of 3.

1 / sqrt(3) = 0.5773

1 - 0.5773 = 0.4226

0.4226 / 2 = 0.2113

so in from the edge by 21.13% of the length from the ends.

Given that we're talking about microinches of deflection, this proves that Starrett's rule of thumb is right on the money. Nevertheless, if the manufacturer indicates the support points used for finishing, those are clearly the ones to use.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks