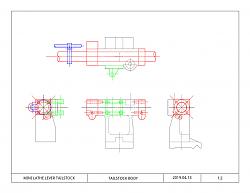

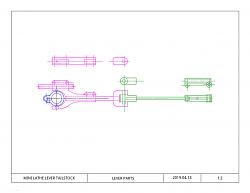

I fixed the original tailstock for my 7x10. Since it’s now extra I made it so it only has a lever to advance tools, similar to tailstocks on many small old plain bench lathes, but mostly it combines features from specialized tailstocks for Myford, South Bend, Schaublin and Boley.

The regular tailstock I had replaced it with is designed to be fitted with a similar lever feed, but the feed screw and bearing hub have to be removed from it first - that’s not difficult but needs a little planning and somewhere to put the parts - I figured mini lathe parts are so light weight it’s easier just to switch between two tailstocks.

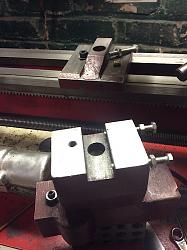

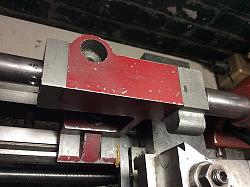

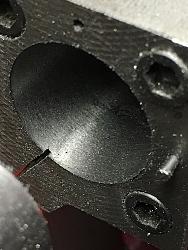

I’ve reused the standard old base and main casting, but modified the base slightly to improve how it seats, and cut the ends off the cylinder part of the casting and replaced them with bolted on new pieces with bosses for adjusting screws. The barrel is new and a little bigger than the original to fit the casting that I rebored between centers in place on the lathe.

It’s less versatile - and harder to make - than retrofit designs like John Stevenson’s and Maszynotwór’s, which retain the regular screw feed as well as the barrel. It’s also less sensitive and takes more space than rack feed ones like Martin Cleeve’s and Stefan Gotteswinter’s.

It works okay, though, and even fully extended seems to be more secure than it ever was before.

The new barrel is 22.5mm diameter and takes ER-16 collets, as well as some M22-1.5 threaded chucks and accessories I have. Maximum travel is about 5”.

Milled an angle on the rear face of the base register with extra screws and matching brass plugs in the main casting, and rebored that using a shear cutter ground from a broken carbide circuit board drill bit

Myford Super 7 lever feed

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks