Lathe tool height gauge. By MKE Gadgets. 10:53 video:

Home-PC (Mar 18, 2022)

Andrew McGregor, please don't take this personally. I latched on to a word, not a person.

? Parallax? Why would anyone build a tool setting periscope, when a 6" scale twixt part diameter and tool tip is a 1 or 2 second endeavor?

Center height gauges; single greatest fetish of amateur lathe operators, and not less than 3 companies willingly cater with expensive gimmicks.

Ever see anyone using or even hinting at using such a thing in a substantially sized lathe; there is a reason!

There are lathes equipped with centerline gauges, typically those without screw tool height adjustments, just shims.

But none are optical; tactile and/ or contact only.

Last edited by Toolmaker51; Mar 17, 2022 at 08:42 PM.

Sincerely,

Toolmaker51

...we'll learn more by wandering than searching...

Toolmaker51 (Mar 17, 2022)

Neither of those, technically.

Mounting that periscope would be laughing stock first and next, being fired.

But years of experience says this type most expedient.......Another in the endless precession of Lathe Center Line Gauges

I don't ridicule any amount of experience, and certainly not HMT.net members, ever.

The internet though, is full of personalities cranking out vacuous content; that detract from efforts 'we' know facilitate lasting, consistent results.

Last edited by Toolmaker51; Mar 17, 2022 at 08:41 PM.

Sincerely,

Toolmaker51

...we'll learn more by wandering than searching...

Home-PC (Mar 18, 2022)

When I started out turning things in my teens on a lathe I bought, I didn't have a Mentor to press for knowledge at least not a mentor in the realm of machine things. My Mentor was a 70 year old Blacksmith. I learned from him when hitting round objects you struck it dead center above the anvil other wise it would move one way or another. I figured out on my little Southbend Lathe on small diameter stock it was easy to find the center with a thin strip of metal held against the stock while moving the cutter to touch it if the strip of metal stayed vertical when held there by the cutter then the cutter was near the center of the material. The exact same as a hammer striking the center of a round piece on an anvil. I also learned that the larger the diameter of the stock the more tedious it was to find the center and subsequently the less it really mattered. I eventually learned about rake angles and chip breakers but that was just my evolutionary process of learning the difference in machining and just turning things . Still to this day when I really want to find the center height especially for when single pointing fine threads on small diameter stock say 2 inches or less I will grab a 6inch machinist pocket scale and let the cutter touch to find true center. But 6 8 10 20 inch material up or down a few thou. or even several thousands when getting really large it just doesn't matter.

Now in defense of the many mirid designs of height centering gages on smaller lathes where the gage doesn't have to be so huge it becomes cumbersome to use I see nothing wrong with them they can be a time saver especially when setting up[ several different cutters in their respective tool holders. A lot of time can be saved using a height gage when the cutters would require rotating the tool post for them to touch the center of a cylinder with the scale between them.

Never try to tell me it can't be done

When I have to paint I use KBS products

Home-PC (Mar 18, 2022), Toolmaker51 (Mar 18, 2022)

I think that one of the worst commercial designs of tool height setting gauge is the type that uses a spirit level. Why is this bad? Because it requires that the lathe bed is set dead level. So this is completely useless for machines mounted in trucks, ships or other mobile situations. For fixed installations I doubt that a high percentage of potential buyers have checked whether their machines are mounted level.

Toolmaker51's suggestion of the 6" ruler or any of the fixed height steel stops are much quicker to use and longer lasting. Plastic stuff gets scratched too easily and when you have some cutting fluid spilt on it then it becomes tiresome to read. Setting tool height is such a simple operation which hardly needs gimic gadgets.

The device in the video is best suited to lathes with flat ways.

Last edited by tonyfoale; Mar 18, 2022 at 04:52 AM.

Toolmaker51 (Mar 18, 2022)

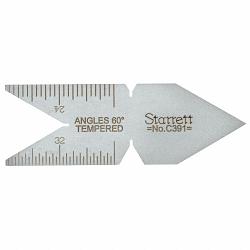

Another almost forgotten way to locate the exact centerline height is to use a thread center gage but it will only work with cutters having the point on the same plane as the top of the tooling such as HSS that has not had a rake grind to it you place the large V notch against the stock in in the chuck and align the point of the cutter with the center of the notch while aligning the pointed end of the gage with the top edge of the HSS.

Most machinist have one of these tools tucked away in their tool box and hardly ever use them anymore I use mine mostly when I have to grind a piece of HSS into a threading tool

Never try to tell me it can't be done

When I have to paint I use KBS products

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks