Captainleeward recently posted his fitment of an internet sourced tacho at

http://www.homemadetools.net/forum/r...eter-mod-71450

I noticed at the rear of his lathe that he had what looks to be a similar DRO to those that I have fitted. Rather than hi-jack his post I show here how I combined both together and fed them from the same power supply.

Click thumbnail for full size.

From the top, tacho, X axis DRO and Z axis DRO. Fitted to a plastic electrical junction box from a hardware store.

The DROs are normally powered by two 3 v button cells in parallel and it is always annoying when the batteries go flat and you are out of spares.

The tacho needs to be fed on 8 to 24 v DC.

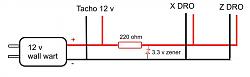

I had a 12 v wall wart which I planned to use for the tacho and as all displays were in the same box it seemed only sensible to toss the batteries and feed the DROs from the same source as the tacho. A 3.3 v zener diode and a 200 ohm resistor was all that was necessary to drop and regulate the supply to the DROs as shown in this diagram.

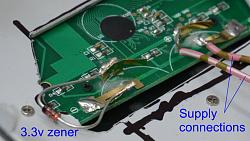

I junked the backs of the DROs, cut component clearance holes in the box lid and used the original screws to hold them in place. i soldered connecting wires directly on to the battery clips. The tacho was designed for panel mounting and so needed no further attention other than cutting the appropriate size hole.

A three pin socket was added for the tach pickup and a socket for the supply from the wall wart.

Closeup of the power connections to one of the DROs.

Sometimes I need to mount a rotary encoder to my spindle and so I needed a method to attach the tach pickup and magnet which would still allow this and space was a bit tight.

Rotary encoder which is sometimes needed.

The magnet for the tach pickup was inset into the spindle lock nut.

The pickup was hot glued to the cover, with a security plate on the outside. This allows the pickup to swing completely out of the way when the cover is opened, thus allowing unhindered use of the encoder.

Warning: The tach pickup is sensitive to the polarity of the magnet. With the magnet facing one way it will work OK, turn the magnet over and it will not work. So prior to final fitting of the magnet you can manually move the magnet back and forth across the pickup to check if the display counts up. There is a small red LED on the back of the pickup which will increase in brightness when the magnet is placed on the end of the sensor with the correct polarity.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks