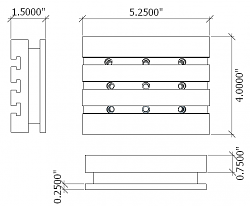

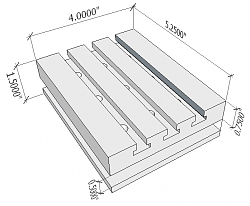

A milling height extension table for a lathe cross slide made from mild steel.

When using a lathe for work it was not designed for I think it needs a bit of help, this brings the work nearer the centre height and reduces the need for packing pieces, it also adds some useful weight to resist cutting forces.

It has enabled me to do some quite heavy milling work, my largest cutter being a 1.5 inch shell mill.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

having trouble in the kitchen; burning

having trouble in the kitchen; burning  all kinds of food.

all kinds of food.

Bookmarks