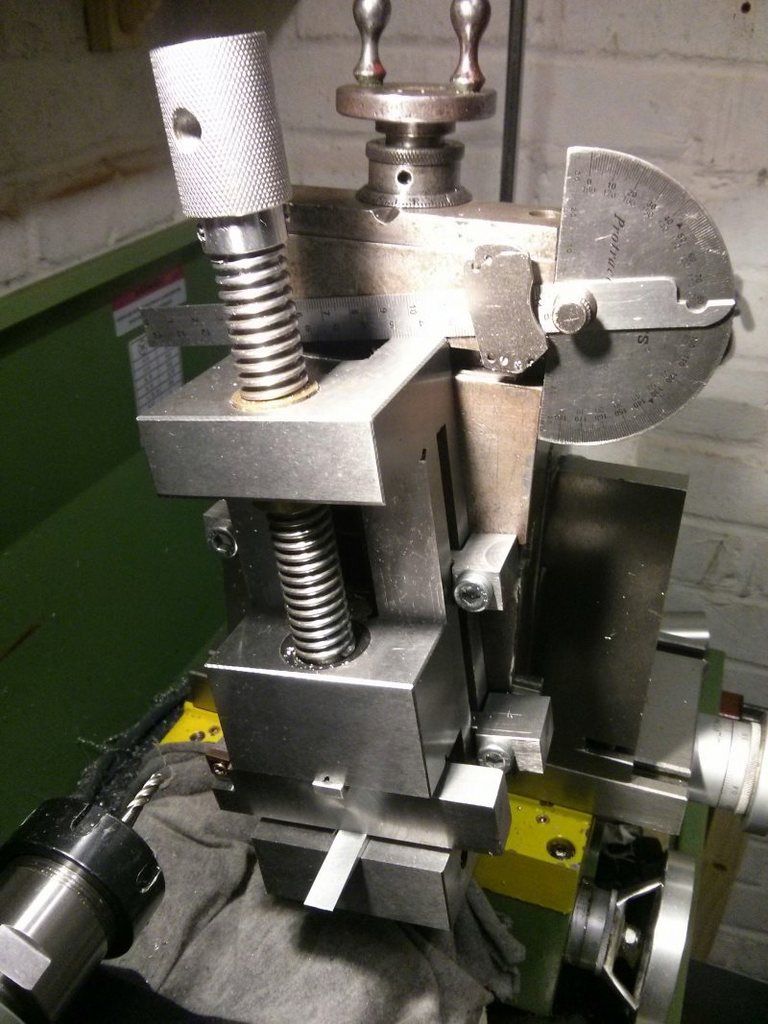

This was one of the first things I tried to mill on lathe, so I spent a lot of extra time setting up to mill angles that I could have done on the bench grinder in seconds.

I need to cut a couple of 6 degree angles and replace the paper shim where I recessed the 6 degree too far.

Set vice at 6 degrees and make some wedges, then set at 10 degrees and wedge work.

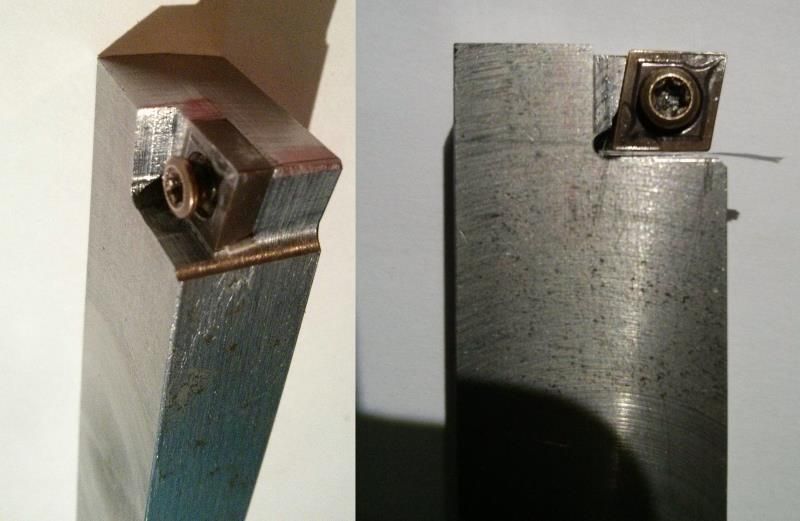

Video of it being abused turning HSS - this requires sharpening on a diamond wheel because most inserts are blunt - except those for aluminium. HSS needs pressure and very sharp inserts or you will just get dust.

good thing most inserts can be sharpened a lot. This had already been 10 times on the diamond wheel. you can see the chip breaker is gone.

This is type of wheel I use RVD 75% 150# 100mm x 20mm Plain Diamond Grinding Wheel Cutter Tools | eBay

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks