Hi again

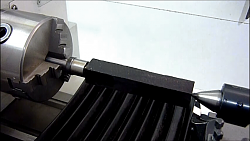

A while back I've made this drive center for turning wood blanks on my mini lathe.

The idea of making this tool was taken from the following picture I found on the web while I was searching for buying an MT3 drive center.

This drive center threads into the spindle of the Unimat DB/SL lathe.

I've made three videos showing the built and use. You will find each video after a series of photos.

I used three different steels, Calmax® and Sverker® 21 tool steels for the body and the prongs and free cutting steel for the threaded adapters’

Total length 71.5mm, shaft diameter 14mm

The diameter of the adapters are 34.8mm and 18.8mm

Total hardening to 58 HRC for the body and the prongs, surface hardening by nitriding for the adapters

400G sandpaper for finishing

The distances between the points are 26.50mm for the large adapter and 12.50mm for the small

I tested the drive center by making a soldering pick. For those of you that don't know, this tool is useful while soldering semi precious or precious metals. It helps in positioning solder pieces as well as it guides the melted solder to the metal surfaces.

This is my old soldering pick (I use it occasionally now)

For making the new one, I used a 3/4 x 3/4 x 4.4” piece of African Blackwood, a piece of brass 18mm x 38mm and a 3/32 x 7” tungsten rod

The ‘nose’ of the tool was made first

Then, was the time to test my drive center

I made a thumb screw using a 6mm brass rod and a 3mm set screw

For expanding the abilities of the tool, I made two more adapters

The diameters are 34.8mm and 24mm

However I came across a problem that I should have thought of in the first place. The problem was that the driving adapter was over-tightened from the cutting force while turning and it was very difficult to un-tighten it from the threaded shaft; I fixed the problem by copying an easy to make wrench I found on the web.

First I made a hole at the side of each adapter

Now, both small and larger adapters have the same body diameter with each other, so with two wrenches the job was done

For making the prongs for the new adapters I used the shanks from two 4.0mm HSS drills

Both adapters were heat treated

The distances between the points are 16.50mm for the small adapter and 20mm for the large

Now to be able to turn wood between centers, I bought an MT3 soft blank arbor and converted it to drive center

The center prong was made using the remaining piece of the 4mm drill shank

The optimal turning length with the live center in the tailstock is 270mm, but it can be increased to 290mm if I use a dead center

All the best

Dimitris

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

PJ

PJ

Bookmarks