Toolpost mounted drill chucks are nothing new, but I had never been enthusiastic about the idea, although I had never tried one, except on a turret lathe. I saw some advantages but they never seem to justify the extra hassle of setting up when you needed it. However, QC (quick change) toolposts have partially removed that objection. Out of curiousity I had intended to try one anyway, one of these days.

"One of those days" arrived when I had some long holes to drill and it seemed like it might be much quicker to clear the flutes using a toolpost mounted drill bit, as it was something that was on my list to make one day I thought that I would make one before doing the holes. I found a suitable block of 4140 in the scrap box just waiting to be useful. I machined dovetails in the back so it fits directly on to the QC post, rather than some that I have seen which bolt into a tool holder.

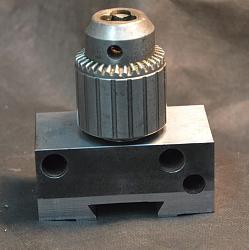

These two photos show the dovetailed channel to fit the QC toolpost.

My original thoughts when I decided to do this was to use a quick change block with a simple parallel hole in it with means for clamping, just like those off the shelf ones for holding large diam. boring bars. In fact I was planning on sharing my big boring bar holder. I was going to get or make an MT2 sleeve with parallel outside, but it seemed to make more sense to bore the block with the Morse Taper directly.

However, I then decided to go for an R8 collet holder instead of the MT2. I have chucks mounted on R8 and MT but I went for R8 simply because it is much easier to make. A parallel bore coupled to a short relatively steep taper is easier to get right than a long shallow MT. My compound rest doesn't have enough stroke to do a full length MT2 in a single setting anyway.

These photos show the toolpost mounted drill chuck, or more generally the R8 mounting block.

After using it for the first time I can say that it definitely fits into the category of "I wish that I had done this ages ago". It is just so much nicer to use than the tail stock for drilling. It is more rigid in all directions, there is no oscillation on the locating key which you sometimes get with a tail stock and of course you can feed and withdraw quickly. With a DRO, drilling to depth is more accurate. If you use an end mill, in a tailstock mounted drill chuck, chatter can be a problem sometimes. That is unlikely to happen with the toolpost holder. I have tested this with several size endmills and it works great. This is another advantage of using a collet holder rather than a Morse Taper, you don't even need to use a chuck, an R8 collet holds a tool much tighter and truer. I can also fit an ER collet chuck in the R8 if necessary

Before trying the toolpost drilling method one of my objections was the time spent aligning the the chuck to the lathe spindle axis. In practice this has turned out to be a non-issue. I have a fixed vertical alignment maintained by a fixed spacer/stop so that only leaves horizontal alignment to worry about each time.

Note the non-adjustable height stop on the top of the block. This ensures reasonable repeatability of the centre height.

For those times when precise alignment is necessary I clock a piece of parallel bar in the chuck from the lathe spindle, as I outlined in a previous post about tailstock alignment. http://www.homemadetools.net/forum/t...ight=tailstock

Clocking the chuck for precise alignment, quick, simple and accurate.

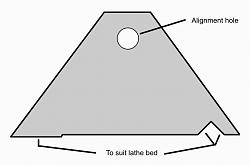

For less precise needs I made a very simple and fast to use alignment tool. In a piece of plate I cut a V to fit the bed V that the saddle uses and on the other side a flat to rest on the bed. Then I put a drill bit in the lathe spindle chuck, offered the plate up to the drill and drilled though, then reamed the hole. Then when I want to use the toolpost chuck, I just chuck up a short piece of ground bar the same size as the hole, put the plate on the bed and adjust the cross slide until the bar fits in the hole.

So although originally a skeptic, my use of toolpost drilling has made me a convert. Well worth the minimal time needed to made it, so simple that there was no need for drawings, CAD or pencil. I am also so glad that I didn't do the obvious and use an MT2, the R8 makes it more useful. The original reason was that it was easier to make. MT2 sleeves are available to fit up inside a R8 sleeve, so I still have the option to use my large drill bits with MT shanks. An MT3 to R8 is overhung but nothing like as much as an extended tailstock. So making a single block only for R8 still gives a pretty good solution for MT2/3 as well.

PS. One of my original concerns about toolpost drilling was that if the centre line of the drill is offset from the toolpost centre bolt then the inline drilling force will create a moment tending to rotate the toolpost out of alignment. This offset is clearly seen in the photos above. I was pleased to discover that my fears were unfounded. Of course we need to remember that normal turning tool bits also apply a moment and so the toolpost friction needs to resist that.

Thanks for watching.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks