I noticed here a while back that the cross feed screw and bronze nut on my 6913 Clausing Lathe was developing quite a bit of backlash so I decided it was time to address the issue, I sent an e-mail to Clausing Mfg. asking for the availability and cost of a new bronze cross feed nut, not by surprise but they still make parts for these older machines and are readily available, the nut was $110.00 and shipping was $22.00 WOW!!! I would hate to know what a lead screw would cost.

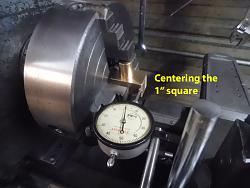

I ordered a piece of 5/8-10 left hand acme lead screw 12”long from roton.com they specialize in lead screws and nuts, the 12”piece was only $26.00 including shipping, I couldn’t find a suitable bronze nut to modify from Roton so I had to decide on what road to take with this bronze nut because Clausing wasn’t getting any of my money, I looked into buying a solid carbide ½” shank #10 preformed acme threading bar but it was astronomical as well $97.00 without shipping, so I decided to make a small boring bar to hold a 1/8” square Cobalt Hss tool bit, the threading bar is made from a piece of 1/2" round by 5” long O-1 steel turned down to 3/8” for 2” long on the end where the tool bit will be, I machined a .140” X .140” square punch from O-1 steel hardened and ground to .130” X .130” square, I drilled a .147” cross hole in the threading bar then broached the .130” square while it was still in the milling machine, the entire boring bar was then hardened and tempered, the 1/8”Hss tool bit was setup in my universal grinding fixture to grind the correct form of 29° and 8° side clearances for cutting the #10 acme thread, the bronze acme nut was made from a piece of 2.250” round by 2.000” long 954 bronze (which I had) I machined it similar to the factory design then chucked it in a 4 jaw chuck and threaded the inside to fit the new Roton lead screw.

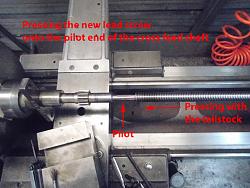

I’m only replacing 12” of the lead screw itself, I’m not making a complete shaft, I done this by cutting off the threaded area on the old lead screw and machined a .4385” dia. pilot on one end 2” back, I then drilled and reamed one end of the new lead screw to .4375” by 2.125” DP, the assembly was setup in the lathe between centers and pressed together, I then drilled and installed a 1/8” roll pin to further secure the joint along with the .001”press fit, I put a dial indicator on the lathe and checked it for straightness finding it was out .006” but that was an easy enough challenge to tackle with a plastic hammer, the unit was then installed into the machine, while watching the machine dial on the cross feed screw I turned the handle left and right finding I had .005” backlash in the screw instead of previously having .055”.

I have included multiple photos making the tools it took to do this job with along with photos and a video of making the new nut and repairing the cross feed screw.

As always thanks for looking and happy machining.

Comments are always welcome.

Doug

<span style="font-family: Calibri"><font size="3"><font color="#000000">

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote That's for the link to roton.com...that will come in handy.

That's for the link to roton.com...that will come in handy.

Bookmarks