So I often find myself in a bind when wanting to drill an offset hole in a workpiece. Drilling from the tailstock only allows for holes drilled dead center in the workpiece. I have had this idea floating around in my head for some time now, so decided to get going and see whether it would work.

The idea was to mount a drill in place of the toolpost. However, mounting a normal handdrill was a bit of a mission and I wanted something dedicated to the lathe.

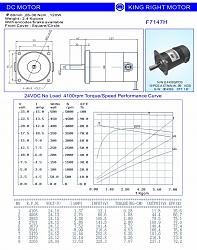

First off was to source a motor, so I paid a visit to our local gate automation go-to guy, who kindly donated a motor from and old Centurion D5 gate motor.

The motor needed a few measurements and modifications, since the mounting method would change completely. The motor was stripped and cleaned.

The front face (top left) which was originally square with 4 mounting holes in the corners, was turned down to just a tad smaller than the motor body.

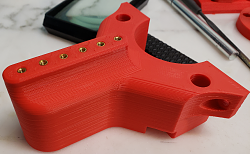

Then, with measurements in hand, I paid a visit to my friendly machine shop that made the new mounting for the toolpost.

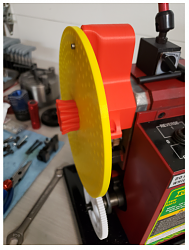

Machined so that it can be flipped over and still be dead center, it fits onto the lathe in place of the toolpost like this.

Or like this

Next was to cut the shaft shorter and turn it down

to accommodate a 3/8 X 24 thread.

Onto which a keyless chuck has been mounted.

I can now drill holes like this.

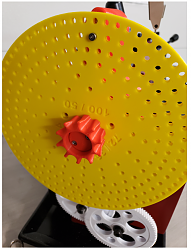

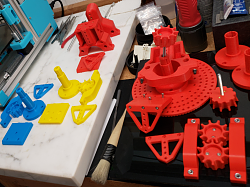

Next up is to get my indexing wheel sorted.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks