These are the short, inverted flare plugs I made using that "broach".

I used a piece of 3/8-24 threaded rod. I faced the parts off in the lathe, drilled a 3/16th's dia. hole about 3/1th's deep and then used a 90 degree C'sink to make the chamfer.

This is the fitting spinning in the lathe.

I then turned it around in the chuck and drilled a .173 dia hole about .25" deep. This is the hole to be "broached". In the pic you can see the starting chamfer I put in with a center drill to guide the broach and help get it started.

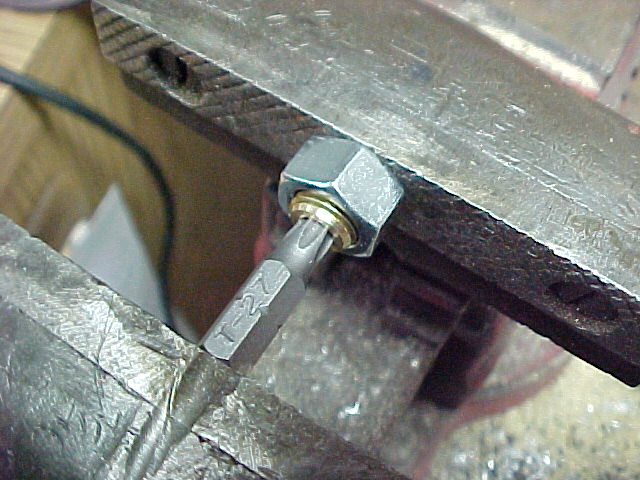

A couple of taps from a hammer set it enough I could get it clamped in the vise.

After pressing it home It took a bit of wiggling to get it out of the brass but doing that didn't seem to hurt the fit or operation of the "new" driver.

Continued in next post.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks