My mechanic neighbor called me up this afternoon, said he is working on a John Deere grader and needed a way to install the axle bearing and seal. It actually takes 2 special tools to accomplish this 1 is simply a 4" OD tube with a 3 3/4" ID with the ends machined true to each other and 9 1/2" long the other is a plate 3/16 to 1/4" thick split diagonally with a center hole large enough to clear the micro sleeve on the spindle.

Here is what I made for him

First I lucked out and found a piece of round tubing the correct OD

cut it squared the ends and did a slight cleanup to the bore

Next I squared a 1/4" Plate to 8x8"

Chucked it in the 4 jaw and made the center hole

the finished tool

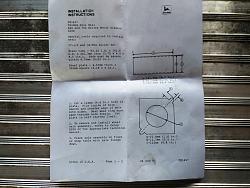

What the manual says

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks