Toolmaker 51 - I like your alternative suggestions but isn't one of the trade marks of Bon Ami, "Hasn't scratched yet".

rendoman (Jul 1, 2018), Toolmaker51 (Jul 1, 2018)

rendoman (Jul 1, 2018)

Toolmaker51 (Jul 9, 2018)

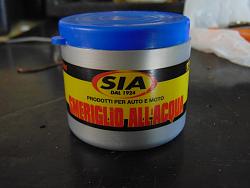

Finally found an emery paste, it's silicon carbide in water solution. It seems not good to spread on the plate, should I dry the carbide and mix with grease or oil maybe?

I'm trying to create a leather pad with wooden dowel and glue. I tried leather contact cement, it seems not enough, I'm trying Vinavil with the tool pressed in the vice. I will try in a couple of days

Here, I use Clover brand lapping compound. It's silicon carbide in oil. I just use the end of a soft wood dowel that has been trued by spinning the end on med. grit sandpaper laying on a flat piece of steel. Then just use the end of the dowel rod on the lapping compound slurry. I usually run around 250 to 500 RPM range. This needs to be a somewhat gentle process. No high speed spindle or heavy down force.

rendoman (Jul 13, 2018), Toolmaker51 (Jul 13, 2018)

Yes Rendoman, water is certain to evaporate while you are trying to jewel the plate. Any reasonably clean oil will give better results. Mix up a paste about the consistency of toothpaste. Too thick the swirls will be hard to see appear. To thin, and whoever does the laundry; well you know the rest!

Sincerely,

Toolmaker51

...we'll learn more by wandering than searching...

rendoman (Jul 14, 2018)

The circles in the test piece look good.

In the patterns I've seen, the circles are overlapped by about the radius of the circle. (The tool is moved about a half diameter before making the next circle.) You might want to make some samples on your test piece to decide how much overlap you think looks best.

---

Regards, Marv

Failure is just success in progress

That looks about right - Mediocrates

rendoman (Jul 16, 2018)

I agree; the swirls appear 'right'. The suggestion I'll make for the pattern; continue with the grid sheet for spacing, and clamp a rail [straight edge] of some kind to guide the plate. It will make following the increments SO much easier.

Sincerely,

Toolmaker51

...we'll learn more by wandering than searching...

I haven't done a lot of jeweling but I did learn early on that the diameter of the swirls need to be of some direct proportion to the size of the item being jeweled. 1 inch diameter swirls look as out of place on a 69 Chevy C 10 firewall as do those on a 31 ford at 2 inches. 1" on the Ford looked great as did the 2" on the Chevy. Probably why a 12" swirl pattern looks better on a ceiling than a 6 inch does

Never try to tell me it can't be done

When I have to paint I use KBS products

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks