This my first post here so I hope that I obey all the rules.

There are a plethora of home-made and low end commercial workshop presses out there which use common one piece hydraulic jacks to generate the required force. However, all that I have seen use the jack in the normal upright position, they simply don't work upsidedown. I have always thought that there had to be a way of inverting a jack and removing the need for the extra moving parts usually seen on these presses.

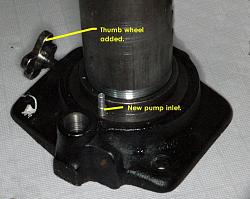

A one piece jack as bought has the pump part at the bottom so that its intake is submerged in oil but there has to be an air volume above the oil level to allow for the changing volume as the shaft exits and retracts in use. When inverted the air rises to what was the bottom and so the pump tries to pump air not oil. My first thought was that if I used an external oil reservoir and bled all the air out of the jack then the problem would be cured. On removal of the outer cylinder I saw another method that would be less sensitive to any entrapped air. I pressed a small hollow barb into the pump intake and extended it with some plastic hose. When inverted the open end of the hose is well submerged in the oil ensuring that the pump only sucks what it should. Rather than deciding between these two methods of allowing the jack to be inverted I decided to do both.

The above photos show the detail of fitting the new oil pickup for the pump. I also added a small wheel to the pressure relief screw for ease of operation. I still had to arrange for an oil feed and return to the reservoir tank. The feed was easy I just tapped for a connection where the original filling hole was. For the return I needed to tap in at the highest point to allow air out, for this I drilled two meeting holes at 90 deg. to each other and tapped the external hole for another connector as shown in the following.

There was just one simple job left to complete the conversion. When you turn a jack upsidedown the action of the pump lever is reversed also. That is, you need to lift the handle to pump the jack. This isn't a natural nor effective way. Fortunately it is easy to fix this, just a question of putting the handle on the other side of the pivot mechanism and welding a stop on the appropriate side. Here it is and also the complete press which was made from stuff that I had lying around, note the Fiat header tank used for the reservoir. A typical HF press is also shown for comparison.

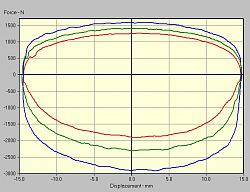

I build and race classic motorcycles and a strong motivation for the press was to service built up crankshafts which have some very tight interference fits and a significant force is required. I was planning on getting a 20 ton jack but a racing friend had bought a HF pipe bender which was terrible for bending the thin walled tube which he wanted. So I bought it from him and used the 16 ton but long stroke jack for the press. I was hopeful that 16 tons would be OK and the long stroke was ideal for a press.

In use the press has exceeded all expectations, it is not used daily but probably weekly and it is used for a lot more tasks than I envisaged. It is much more convenient to use than the rightwayup presses that I had previously used.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

~PJ

~PJ

)

)

Bookmarks